1.2.1 Carriage and Guide Rail

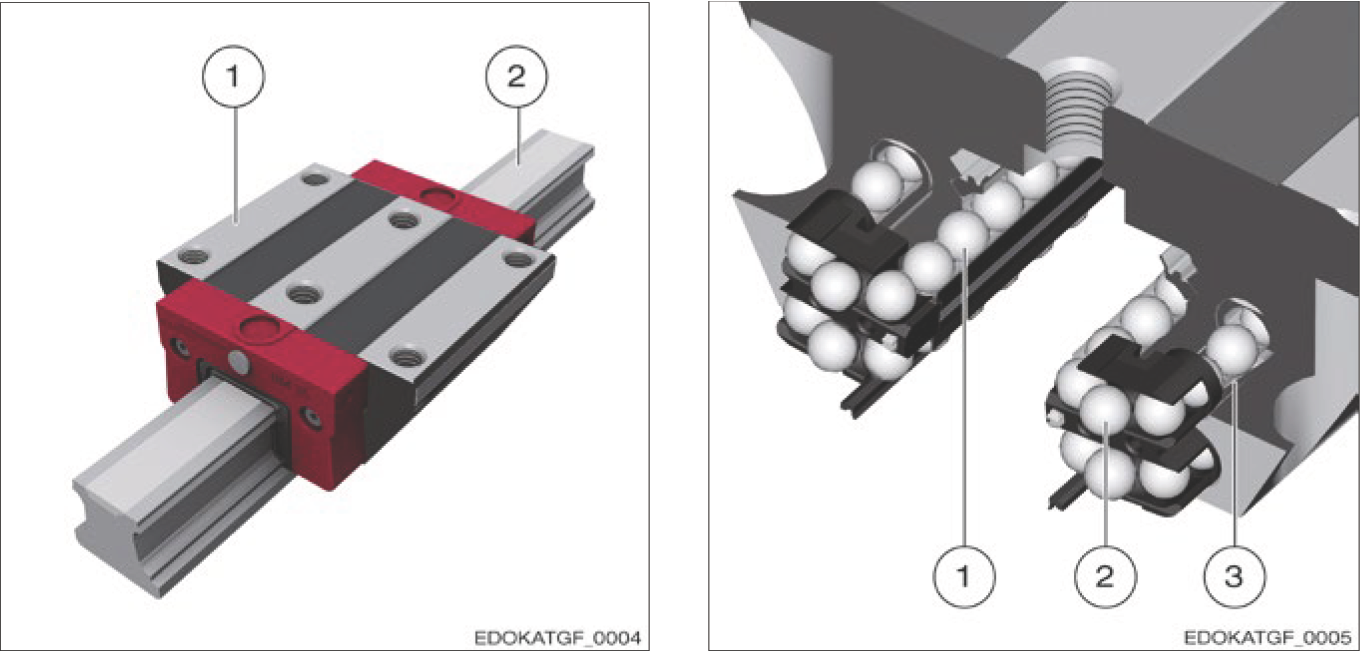

The SCHNEEBERGER MONORAIL guideway system consists of guide rails and carriages containing rolling elements. The rolling elements run in raceways enclosed within the carriage, enabling the carriage to achieve unlimited linear motion on the guide rail. The rolling element raceways are divided into load zones and return zones.

Figure 1.5 - Carriage and guide rail construction: 1 Carriage 2 Guide rail

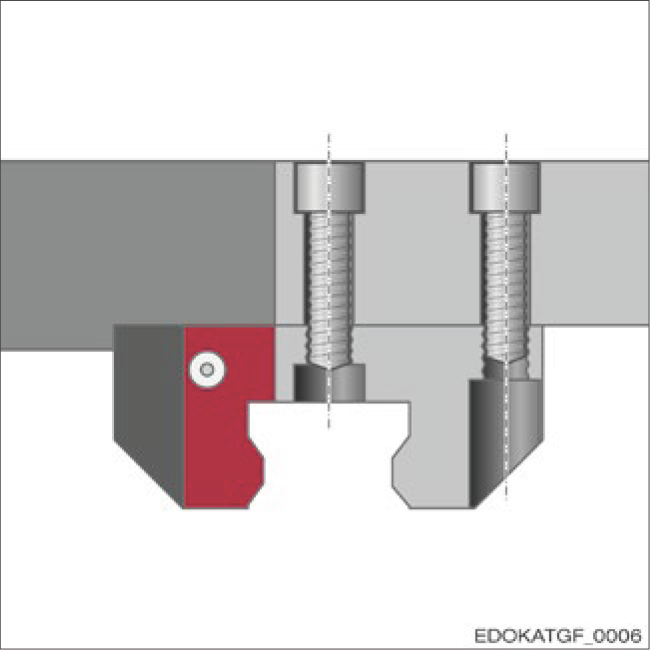

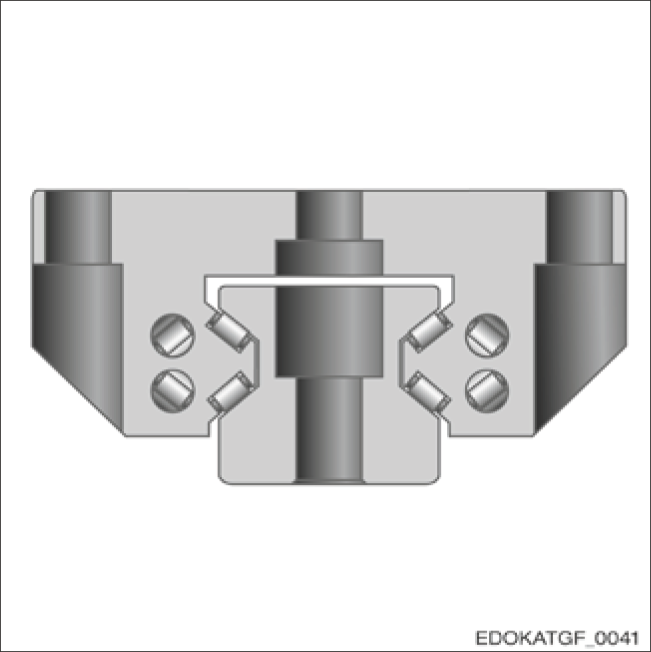

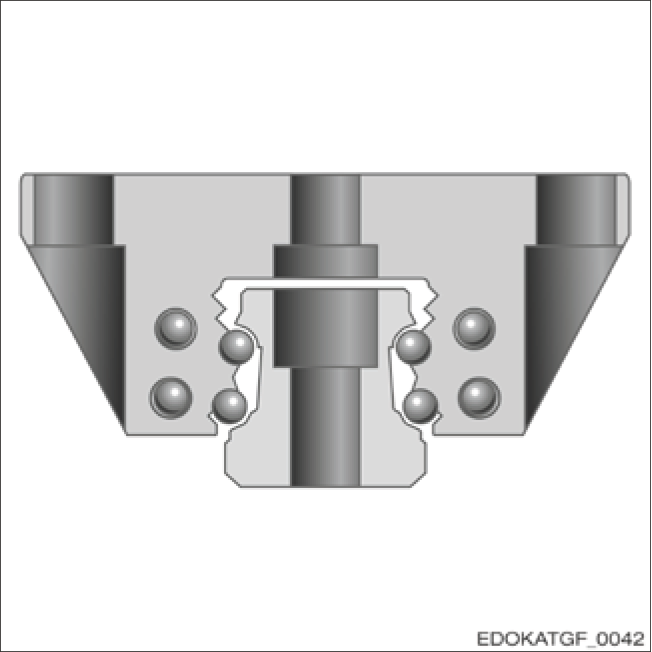

Rolling Element Recirculating Unit

The rolling element recirculating unit is located inside the carriage and contains the load zone and return zone. In the load zone, rolling elements bear and transmit external loads; in the return zone, rolling elements return in an unloaded state.

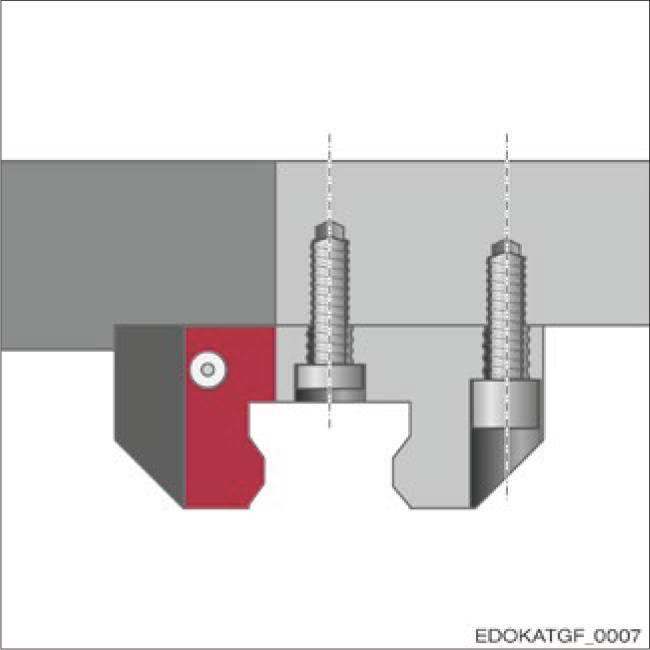

Reference Surfaces and Fixing

SCHNEEBERGER MONORAIL guideways are fixed to the surrounding structure via the guide rail base surface and lateral locating surface. The support surface of the guide rail base is designed by SCHNEEBERGER as a full surface area to achieve maximum possible contact area.

The lateral locating surface is standard designed on one side for lateral support and orientation with the connecting structure. Dual-sided locating surfaces can also be provided upon request.

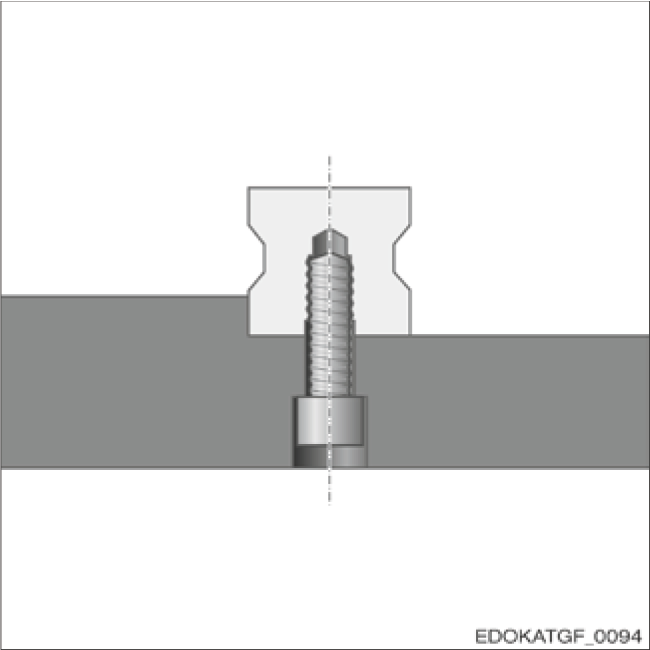

Fixing Hole Configuration

Using threaded fixing holes

Using carriage fixing holes as through holes

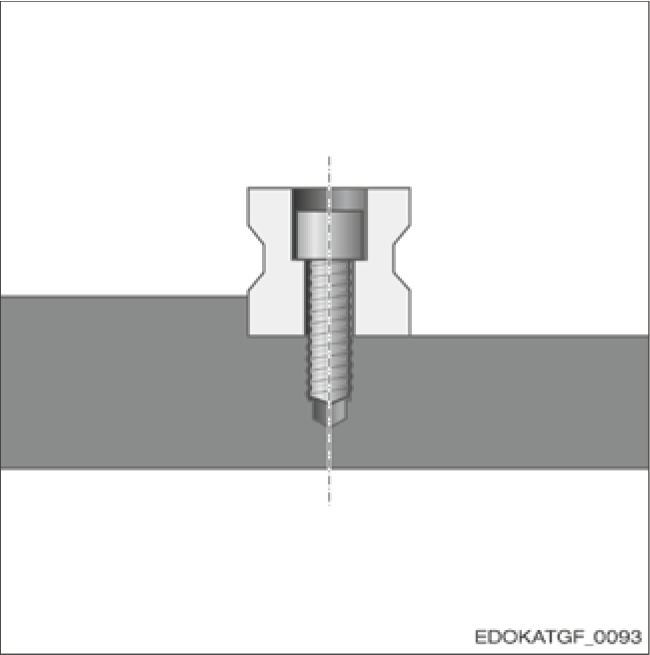

Guide rail with through holes

Guide rail with threaded fixing holes from below

Accuracy Requirements

The quality of mounting and locating surfaces and their mutual positional relationship affects the geometric accuracy and service life of guideways. Therefore, these surfaces need to be precision machined to high quality standards.

1.2.2 Individual Components and Accessories

SCHNEEBERGER MONORAIL guideway carriages consist of multiple components. The core is the load-bearing body made of high-grade ball bearing steel, with fixing holes and raceways and return bores for rolling elements.

Rolling Elements

Rollers or balls are used as rolling elements, all made of hardened ball bearing steel.

Guiding Elements

Another component of the carriage body is the synthetic guiding element with integrated longitudinal wipers.

Recirculating Unit

The recirculating unit for rolling elements is also a component of the carriage body.

End Plate

The end plate with integrated transverse wipers seals the carriage front and is responsible for lubricant distribution.

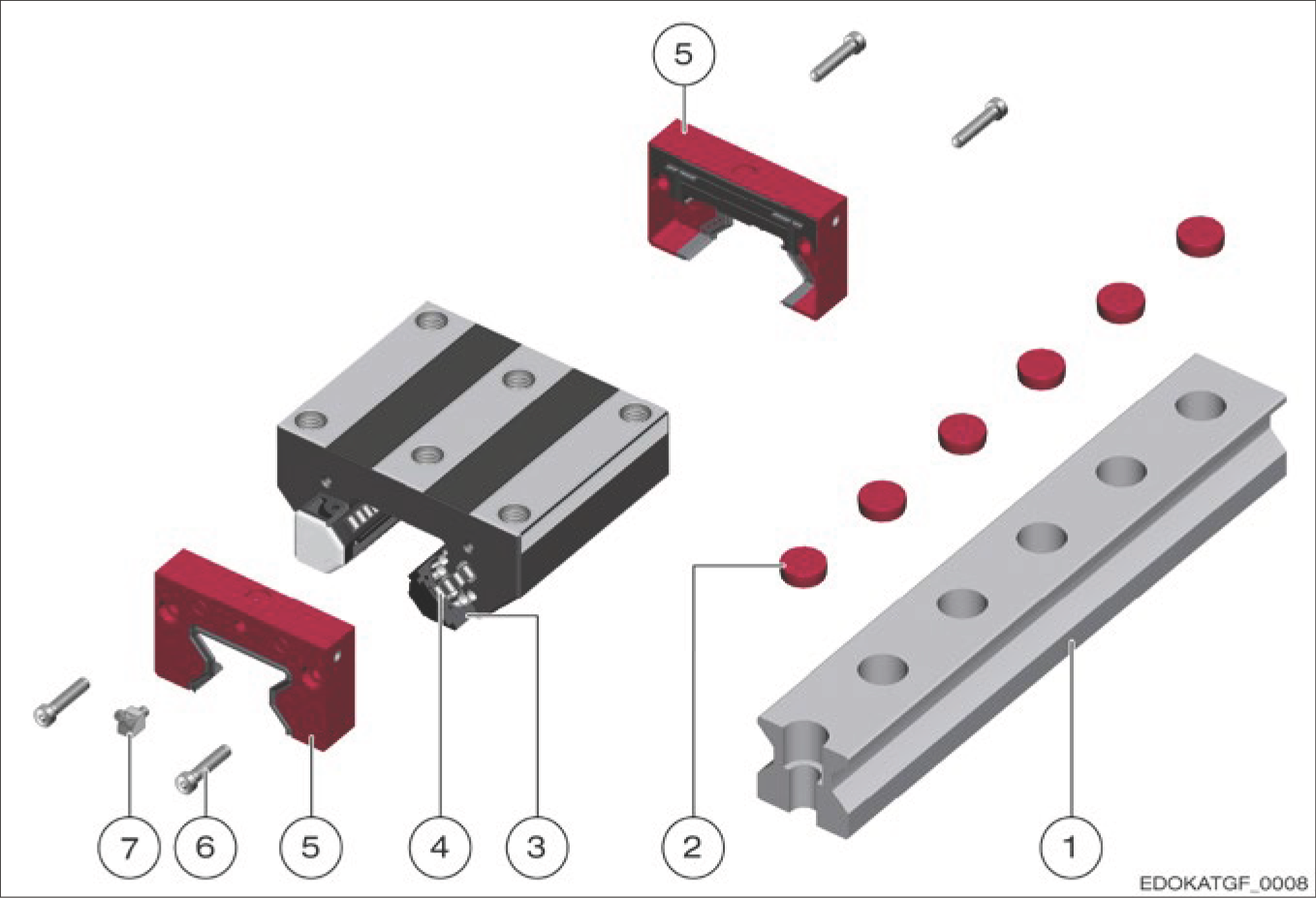

Figure 1.6 - Basic equipment of MONORAIL MR roller guideway

Basic equipment components:

Accessory Options

Carriages can be upgraded with accessories, such as additional wipers, metal scrapers, or lubrication plates, which are mounted in front of the end plate to support system adaptation for specific applications.

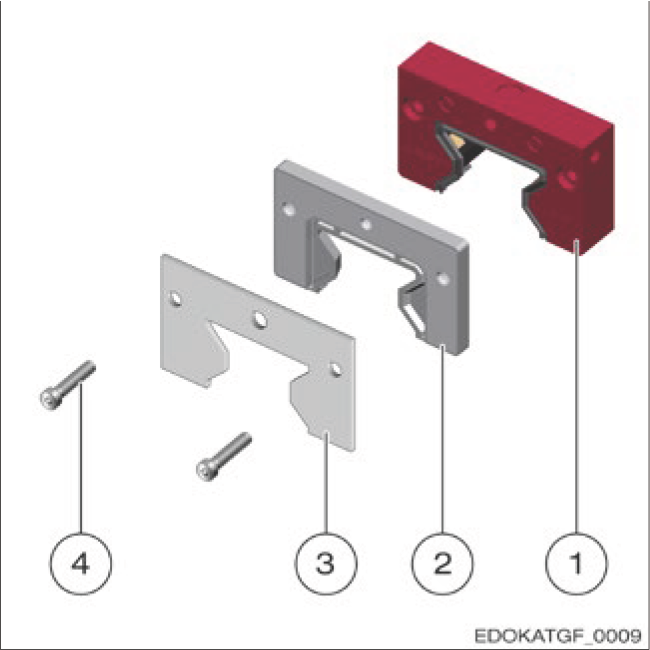

Figure 1.7 - Accessory options for MONORAIL MR roller guideway

Accessory options:

1.2.3 Types and Design Principles

Applicable Standards

SCHNEEBERGER MONORAIL guideways are available in various sizes and types. To establish consistent standards for these machine elements, the most important design elements have been compiled in industry standard DIN 645 Part 1.

Rolling Element Arrangement

The number and arrangement of rolling element rows depends on rolling element shape, roller contact, available installation space, transmittable forces, and other factors. There are guideways with two, four, or more rows of rolling elements.

Guideway Type:

SCHNEEBERGER MONORAIL roller guideway

Geometry:

- 4 rows

- Line contact

- O-geometry

SCHNEEBERGER Products:

- MONORAIL MR

- MONORAIL AMS 3B

- MONORAIL AMSABS 3B

- MONORAIL AMSA 3L

Guideway Type:

SCHNEEBERGER MONORAIL ball guideway

Geometry:

- 4 rows

- 2-point contact

- O-geometry

SCHNEEBERGER Products:

- MONORAIL BM

- MONORAIL BZ

- MONORAIL AMS 4B

- MONORAIL AMSABS 4B

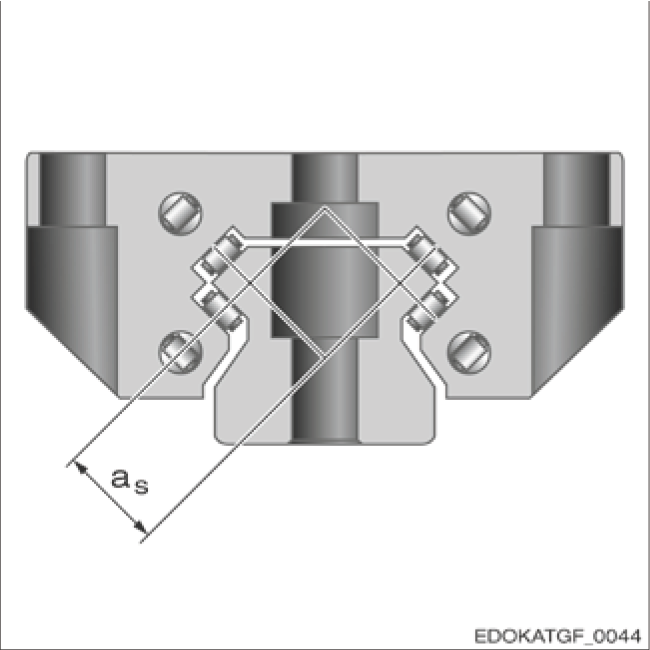

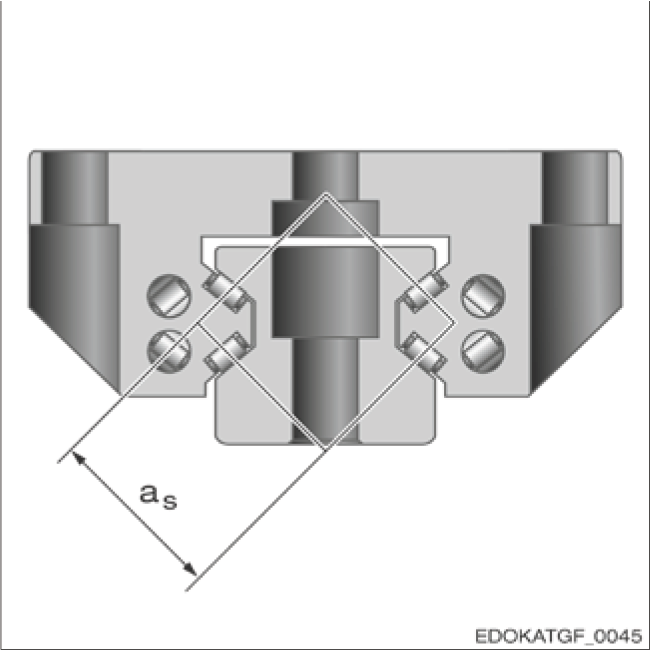

X-Geometry and O-Geometry

The raceway arrangement of profiled rail guideways is distinguished between X-geometry and O-geometry. With so-called O-geometry, the rolling element raceways are offset by 90°, enabling a larger internal spacing. Therefore, guideways can consistently withstand high load forces and moments from all directions.

X-geometry with spacing as

O-geometry with spacing as

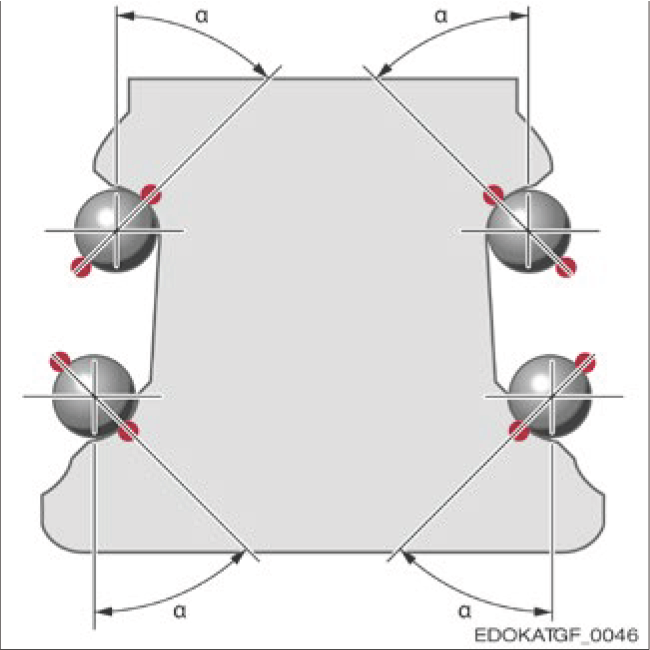

Contact Angle

SCHNEEBERGER MONORAIL guideway raceways are arranged at specific angles to enable them to withstand forces from different directions. The contact angle α is defined according to DIN ISO 14728 as the angle between the direction of force acting on the guideway and the contact line.

Contact angle of the rolling element with the guide rail

Contact angle parameter:

SCHNEEBERGER Contact Angle

All SCHNEEBERGER MONORAIL guideways have a contact angle of α = 45°, enabling them to simultaneously withstand high load forces from all directions.

1.2.4 Materials

SCHNEEBERGER MONORAIL guideway rails and carriages use high-grade tool steel and various high-grade plastics as materials. Non-ferrous metals and aluminum are used for some accessories.

| Component | Material |

|---|---|

| Guide rail | Ball bearing steel, raceway or entire rail hardened |

| Carriage body | Ball bearing steel, body fully hardened |

| Rolling elements | Ball bearing steel, hardened |

| End plate | PA, injection molded |

| Recirculating unit | POM and polyamide, injection molded |

| Additional wiper | NBR or FPM (Viton) for sealing lips, stainless steel for carrier plate |

| Metal scraper | Stainless steel, corrosion-resistant |

| Reading head | Stainless steel, corrosion-resistant |

1.2.5 Hardening Processes

To achieve sufficiently high load capacity and long service life, the surfaces of profiled rail guideways in contact with rolling elements must have high surface hardness. Different hardening processes are used for rails and carriages to ensure optimal performance.

Guide Rail Hardening

For guide rails, the rolling element raceways can be surface hardened (induction hardening), or the entire rail can be fully hardened.

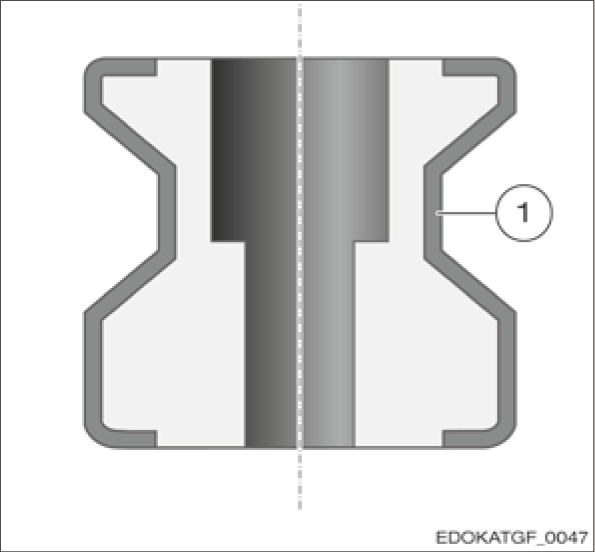

Inductively hardened guide rail with hardness zone (1) based on the example of an MR guide rail

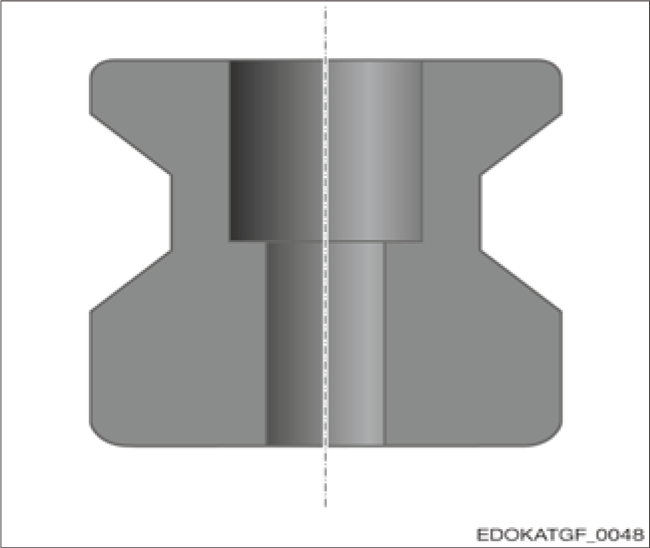

Fully hardened guide rail based on the example of an MR guide rail

Inductively Hardened Guide Rail

Induction hardening is a surface hardening method that only hardens the rolling element raceway area of the guide rail. This method uses high-frequency current to generate heat on the surface, then rapidly cools to form a hardened layer.

Characteristics of inductively hardened guide rails:

- Only raceway area hardened

- Hardening depth controllable

- Guide rail core retains original toughness

- Suitable for larger size guide rails

Fully Hardened Guide Rail

Full hardening is heat treatment of the entire guide rail, making the entire component achieve uniform high hardness. SCHNEEBERGER's fully hardened guide rails provide additional advantages, particularly suitable for harsh environmental conditions.

Characteristics of fully hardened guide rails:

- Entire guide rail uniformly hardened

- Surface hardness reaches 58-62 HRC

- All surfaces have high wear resistance

- Suitable for applications requiring high surface quality

Advantages of Fully Hardened Guide Rails

- Long wiper service life - hardened surface reduces wear

- Surface can be used as sliding surface for protective covers

- Protects guide rail from chip and contaminant ingress

- Better performance in corrosive environments

- Can be ground for higher surface quality

Carriage Hardening

The load-bearing body of the carriage is made of high-grade ball bearing steel and is fully hardened (through hardened). This ensures the carriage has sufficient hardness and wear resistance to withstand continuous rolling contact loads.

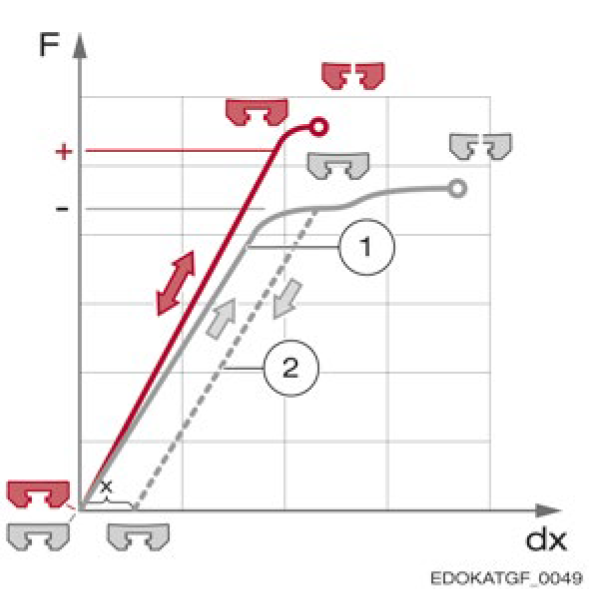

Force F is applied against deformation dx up to breaking point

Legend:

Red line - Fully hardened

Grey line - Inductively hardened

Advantages of Fully Hardened Carriages

When subjected to excessive loads, inductively hardened carriages undergo plastic deformation, with deformation x continuously increasing. Fully hardened carriages maintain elastic behavior up to the breaking point, providing more predictable performance.

Characteristics of carriage hardening:

- Carriage body fully hardened

- Rolling element raceways have high surface hardness

- Ensures optimal fit with rolling elements

- Provides long-term stable geometric accuracy

Selection of Hardening Process

Selection of the appropriate hardening process depends on various factors, including guide rail size, application environment, and performance requirements. SCHNEEBERGER provides different hardening options according to product series and customer needs.

| Component | Hardening Method | Hardening Range | Surface Hardness |

|---|---|---|---|

| Guide rail (induction hardened) | Induction hardening | Raceway area only | 58-62 HRC (raceway) |

| Guide rail (fully hardened) | Through hardening | Entire guide rail | 58-62 HRC (all surfaces) |

| Carriage | Full hardening | Entire carriage body | 58-62 HRC |

| Rolling elements | Full hardening | Entire element | 60-64 HRC |