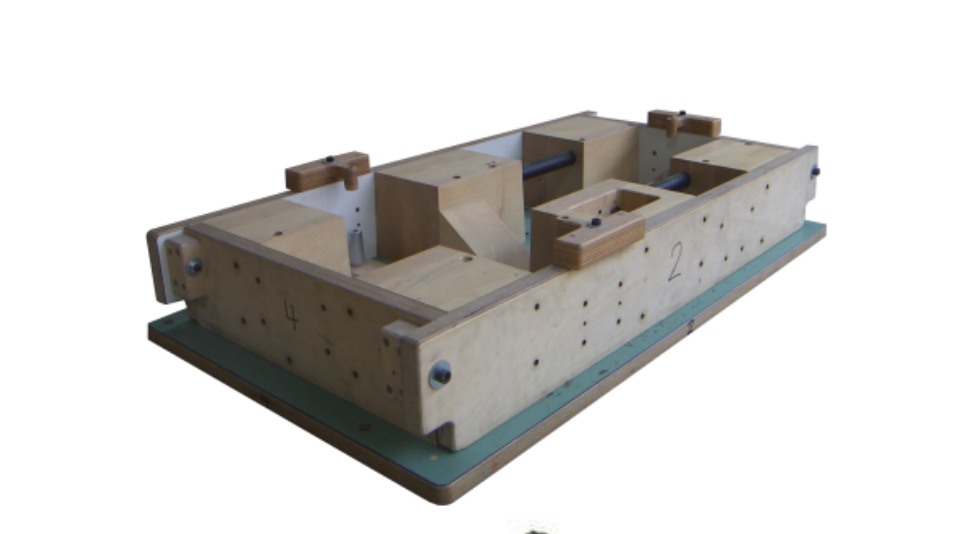

- High-strength composite board frame with polymer surface, for prototype testing

- Service life: 2-3 pieces

Casting Technology Overview

- Molds

- Embedding Technology

- Bonding Technology

- Millable Layer Technology

- Precision Replica Casting

- Steel Structure Filling

Molds

Simple Molds: Wooden Molds

Standard Molds: Steel Molds

- For high-volume production

- Design service life: ~1000 pieces

Composite Molds

Wood Frame with Aluminum Interior

- Wooden structural frame with aluminum interior surface

- Design service life: 20-30 pieces

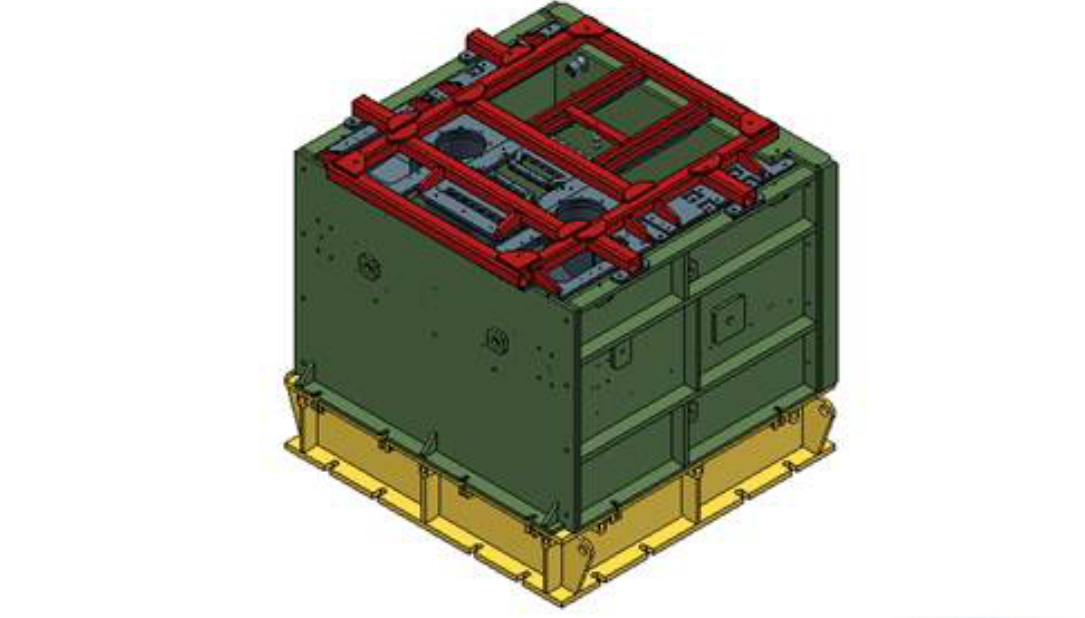

Steel Frame with Aluminum Core

- Steel mold frame with aluminum components

- Aluminum parts replaced based on wear conditions

- Design service life: ~200 pieces

Steel Frame with Nylon Components

- Steel frame with nylon (special plastic) components

- Plastic parts replaced based on wear conditions

- Design service life: ~20 pieces

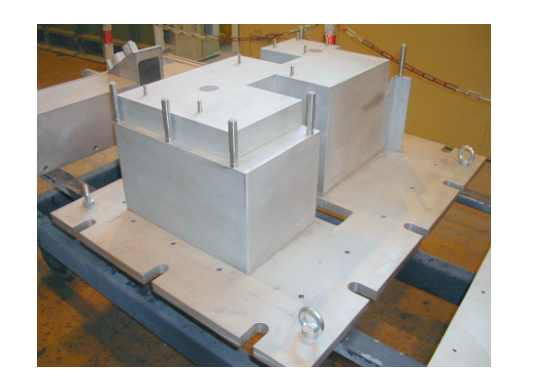

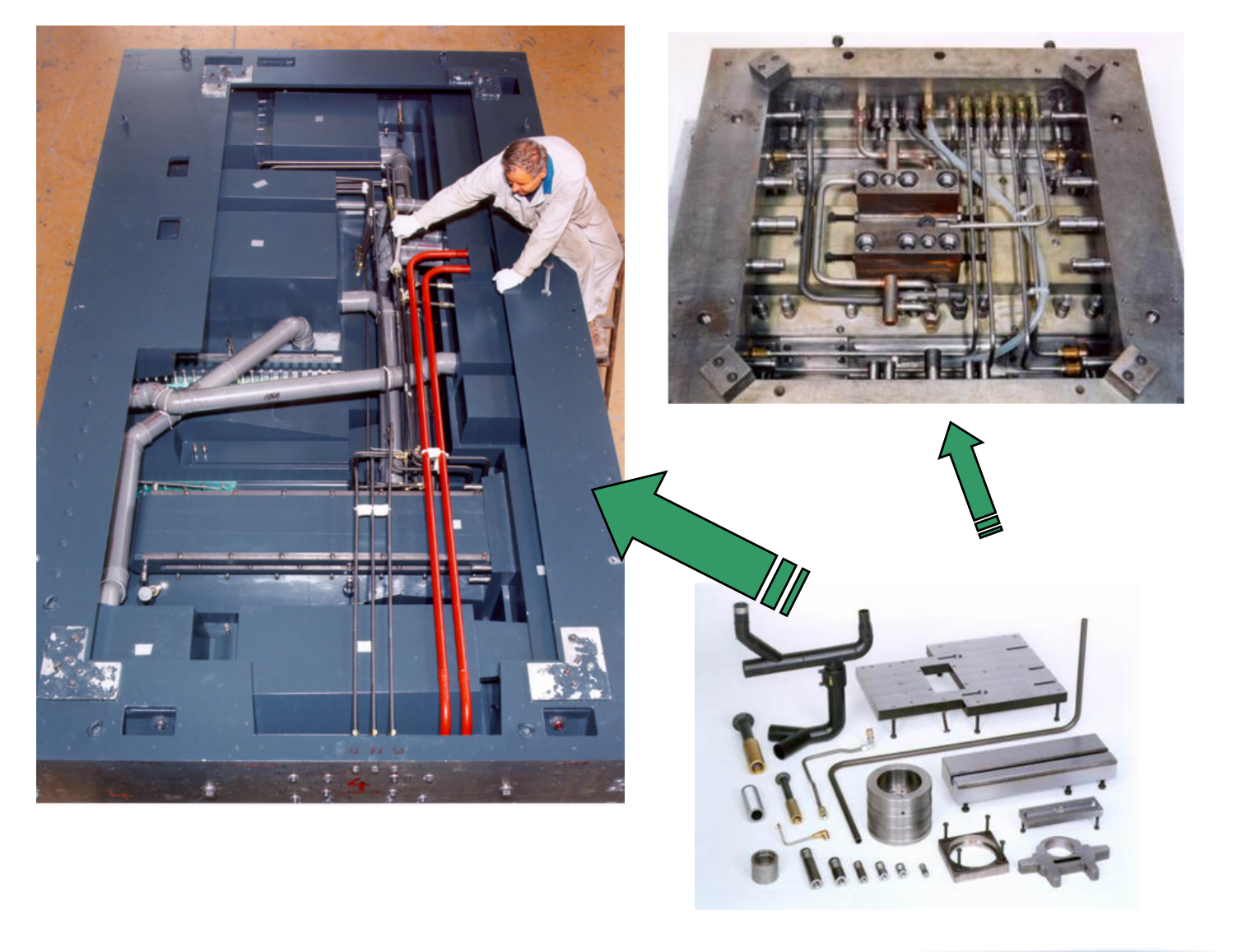

Embedding Technology

- High integration capability

- Precise positioning

- Reliable anchoring

Embeddable Components

- Air and oil passages

- Water pipes and cables

- Threaded insert holes

- Guide rail steel strips

- Various pipe fittings

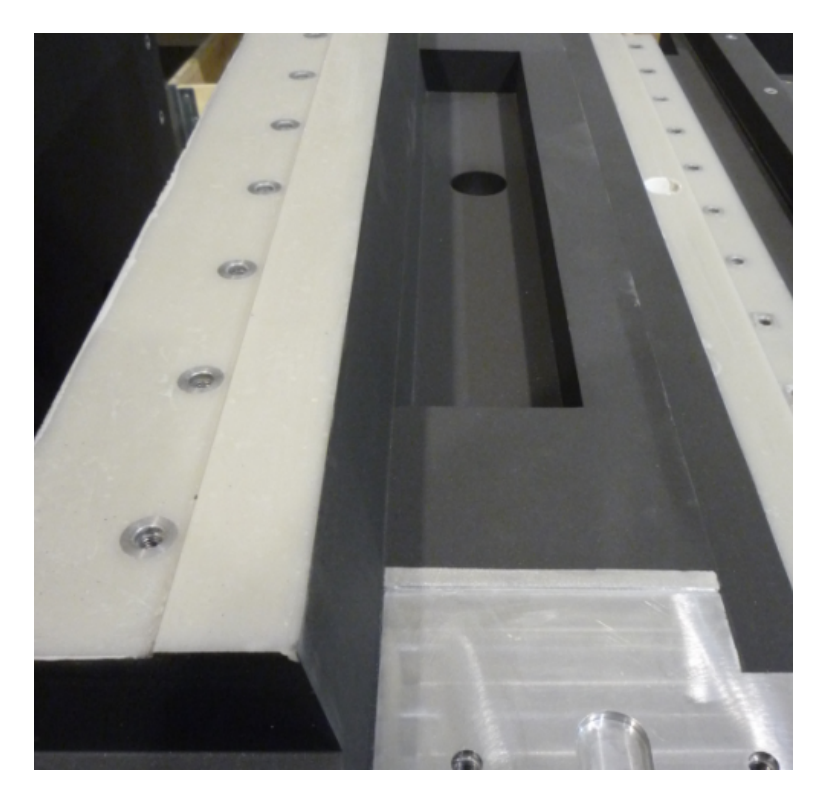

Millable Material

- Standard milling process

- Lower cost

- No special casting tooling required

Process Overview

- Special material formulation

- Pre-cast in mold

- Similar to nylon milling

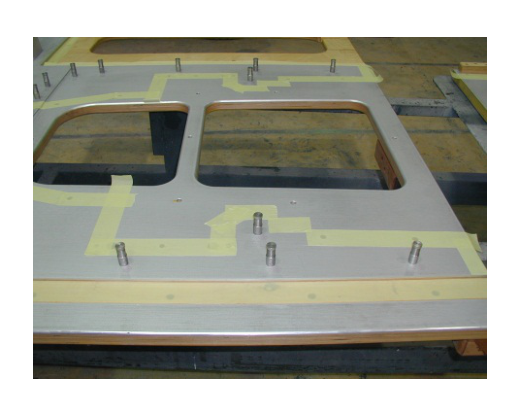

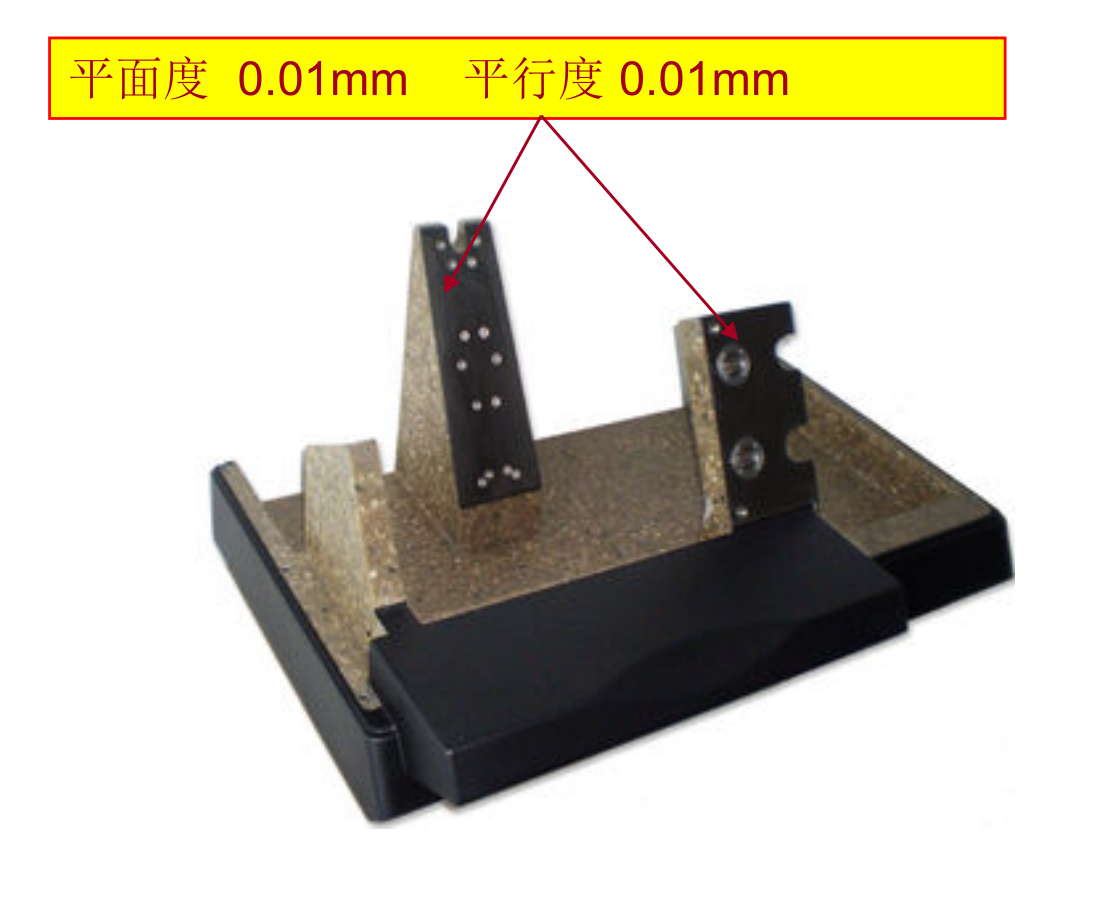

Precision Replica Casting

Flatness 0.01mm Parallelism 0.01mm

- Very high precision

- Lower material cost

- Lower quality cost (repairable)

- High surface hardness and wear resistance

Process Overview

- Special precision tooling positioning

- Mineral material extrusion injection

Steel Structure Filling

- Improved structural rigidity

- Enhanced vibration damping

- Short production cycle

- Integration of various embedded parts

- No additional mold costs

- Suitable for prototypes or extra-large machine bodies