General Information

The precision of fits and the geometrically correct design of all adjacent parts have a direct influence on the accuracy requirements and dynamic characteristics of the bearing.

In the case of the highest requirements, tolerances and fits should be restricted accordingly.

Please refer to the structural design notes in the general catalog chapter.

Surface Roughness Requirements

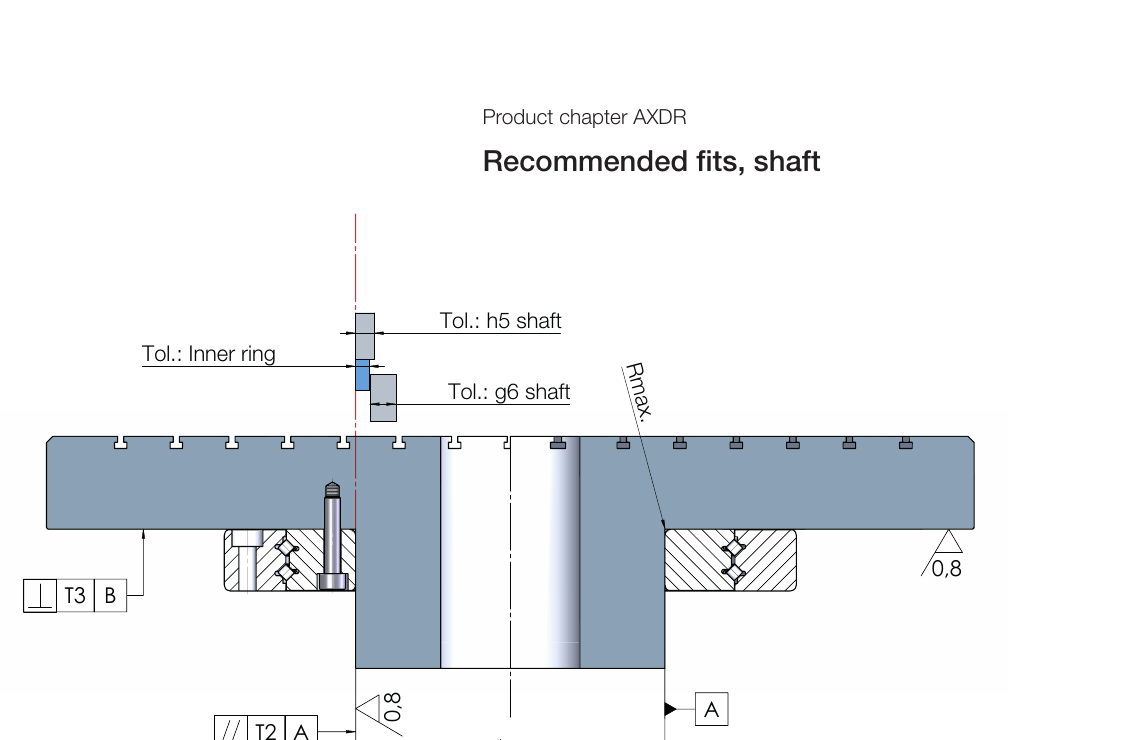

Ra 0.8 μm - Recommended surface roughness for shaft fit surfaces

Rotating Inner Ring

On the rotating shaft, the bearing inner ring should be supported over the entire surface, and the shaft should be designed according to h5 fit. This way, the bearing bore tolerance produces a transition fit tending toward a clearance fit.

Maximum Precision Requirements

For the highest precision requirements with rotating inner rings, a 0 μm clearance fit must be targeted; existing clearance fits may increase radial runout. In the case of clearance fit design, please refer to the instructions in the "Adjacent Construction Design" chapter.

High Dynamic Characteristics Requirements

At higher speeds (ndm > 35,000 mm/min) and longer operating times, interference fits must not exceed 5 μm.

Stationary Inner Ring

A stationary bolt-connected inner ring does not require a special fit and can also be mounted with clearance to the shaft.

Due to the solid ring, AXDR bearings are less sensitive to non-positively locked shafts than AXRY bearings. However, reduced shaft rigidity and possible radial runout problems or rotating shaft displacement during overload must be accepted.

Radial Runout Measurement Note

Radial runout measurements using a centering table and mounted measuring ball do not match catalog values. In such precisely centered measurements, only the radial runout of the raceway and form errors of the measuring structure are measured. myonic radial runout values include radial runout error of the raceway and roundness of the bore.

Shaft Fit Tolerance Table

| Model | Shaft Ø d [mm] | Bearing Bore Tolerance Range [mm] | Stationary Inner Ring | Rotating Inner Ring | ||||

|---|---|---|---|---|---|---|---|---|

| Shaft Tolerance g6 [mm] | T1, T2, T3 [μm] | Shaft Tolerance h5 [mm] | T1 Roundness [μm] | T2 Parallelism [μm] | T3 Perpendicularity [μm] | |||

| AXDR 80 | 80 | 0 / -0.009 | -0.010 / -0.029 | 5 | 0 / -0.013 | 3 | 1.5 | 3 |

| AXDR 100 | 100 | 0 / -0.022 | -0.012 / -0.034 | 6 | 0 / -0.015 | 4 | 2 | 4 |

| AXDR 120 | 120 | 0 / -0.012 | -0.012 / -0.034 | 6 | 0 / -0.015 | 4 | 2 | 4 |

| AXDR 150 | 150 | 0 / -0.016 | -0.014 / -0.039 | 8 | 0 / -0.018 | 5 | 2.5 | 5 |

| AXDR 160 | 160 | 0 / -0.018 | -0.014 / -0.039 | 8 | 0 / -0.018 | 5 | 2.5 | 5 |

| AXDR 180 | 180 | 0 / -0.020 | -0.015 / -0.044 | 10 | 0 / -0.020 | 7 | 3.5 | 7 |

| AXDR 200 | 200 | 0 / -0.023 | -0.015 / -0.044 | 10 | 0 / -0.020 | 7 | 3.5 | 7 |

| AXDR 210 | 210 | 0 / -0.015 | -0.015 / -0.044 | 10 | 0 / -0.020 | 7 | 3.5 | 7 |

| AXDR 260 | 260 | 0 / -0.018 | -0.017 / -0.049 | 12 | 0 / -0.023 | 8 | 4 | 8 |

| AXDR 325 | 325 | 0 / -0.023 | -0.018 / -0.054 | 13 | 0 / -0.025 | 9 | 4.5 | 9 |

| AXDR 350 | 350 | 0 / -0.023 | -0.018 / -0.054 | 13 | 0 / -0.025 | 9 | 4.5 | 9 |

| AXDR 395 | 395 | 0 / -0.025 | -0.020 / -0.060 | 16 | 0 / -0.027 | 10 | 5 | 10 |

| AXDR 460 | 460 | 0 / -0.030 | -0.020 / -0.060 | 16 | 0 / -0.027 | 10 | 5 | 10 |

| AXDR 580 | 580 | 0 / -0.035 | -0.022 / -0.066 | 18 | 0 / -0.030 | 13 | 6.5 | 13 |

| AXDR 650 | 650 | 0 / -0.038 | -0.024 / -0.074 | 19 | 0 / -0.036 | 13 | 6.5 | 13 |

Notes

Important: Shaft Surface Quality

- Surface roughness: Ra ≤ 0.8 μm

- Roundness: According to model requirements (see table above)

- Parallelism: Should be within tolerance range

- Perpendicularity: Perpendicularity of shaft shoulder to shaft journal is important

- The above data are recommended values; actual applications may require adjustment based on specific conditions

- High-precision applications may require tighter tolerances

- All fit surfaces should be cleaned and inspected before installation

- myonic AXDR bearing bore and outside diameter are manufactured according to P5/DIN 620 standards