Mineral Casting Machine Bases

Machine bases represent one of the most important application areas for mineral casting. SCHNEEBERGER mineral casting machine bases combine superior vibration damping, lightweight design, and high integration capability to provide ideal foundation structures for precision machinery.

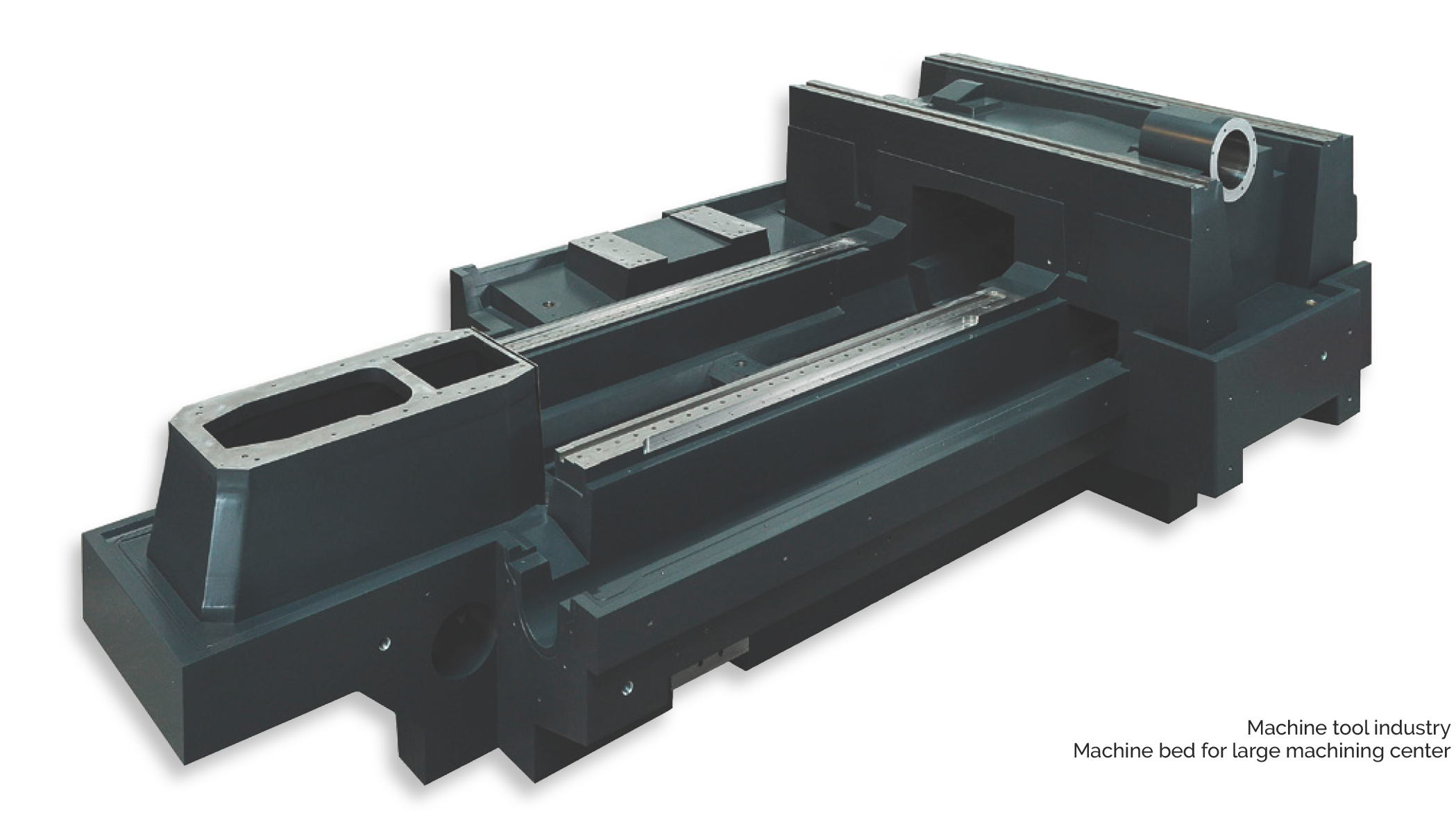

Large machining center mineral casting base

Core Advantages

Product Specification Range

Integration Capability

Mineral casting machine bases can integrate various functional components directly during the casting process, achieving the goal of "cast once, deliver complete."

Guide Systems

- Linear guide mounting surfaces

- Slideways

- SCHNEEBERGER linear bearings

Drive Systems

- Linear motor magnet tracks

- Ball screw mounting seats

- Rack support surfaces

Fluid Systems

- Coolant channels

- Pneumatic passages

- Lubrication lines

Electrical Systems

- Cable channels

- Sensor mounting seats

- Junction box provisions

Case Study: A single mineral casting base can embed 284 different parts including threaded inserts, dowel sleeves, and pipe fittings, significantly reducing subsequent assembly work.

Application Types

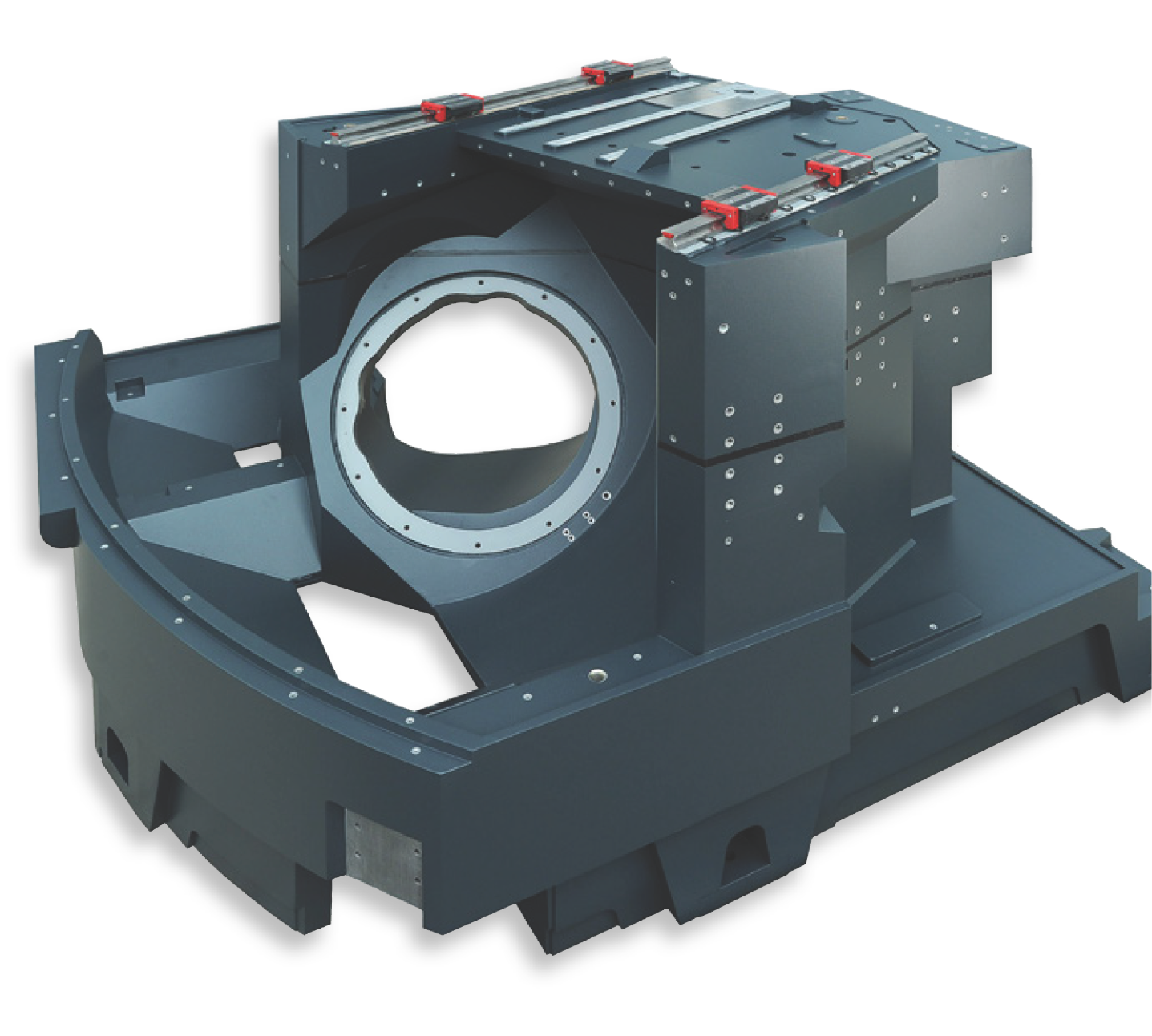

Machining Center Bases

Machine bases for 5-axis machining centers, horizontal machining centers, and vertical machining centers, providing stable machining foundations.

Grinding Machine Bases

Precision bases for surface grinders, cylindrical grinders, and internal grinders, meeting high-precision machining requirements.

Gantry Structures

Columns and crossbeams for large gantry machining equipment, combining stiffness and damping performance.

Metrology Equipment Bases

Stable bases for coordinate measuring machines and optical measurement equipment, ensuring measurement accuracy.

High-demand 5-axis machining machine structure

Comparison with Traditional Materials

| Comparison Item | Mineral Casting Base | Gray Cast Iron Base | Welded Steel Structure |

|---|---|---|---|

| Vibration Damping | ★★★★★ | ★★☆☆☆ | ★☆☆☆☆ |

| Weight (same volume) | Light (1/3 steel) | Heavy | Heaviest |

| Parts Integration | High (284+ parts) | Medium | Low |

| Machining Operations | Few | Many | Most |

| Lead Time | Short | Medium | Long |

| Total Cost | Low (save 30%) | Medium | High |

| Environmental | Fully recyclable | Recyclable | Recyclable |

Design Services

SCHNEEBERGER provides complete services from design to delivery, ensuring machine bases meet your exact requirements.

Requirements Analysis

Understand technical specifications, load requirements, integration needs

Design Review

Structure optimization, FEM analysis, manufacturability assessment

Manufacturing

Cold casting process, insert integration, surface treatment

Quality Delivery

Quality inspection, packaging and transport, technical support