MONORAIL BM WR/SR Corrosion-Resistant Ball Guides

Corrosion-Resistant Ball Profile Linear Guides

Product Overview

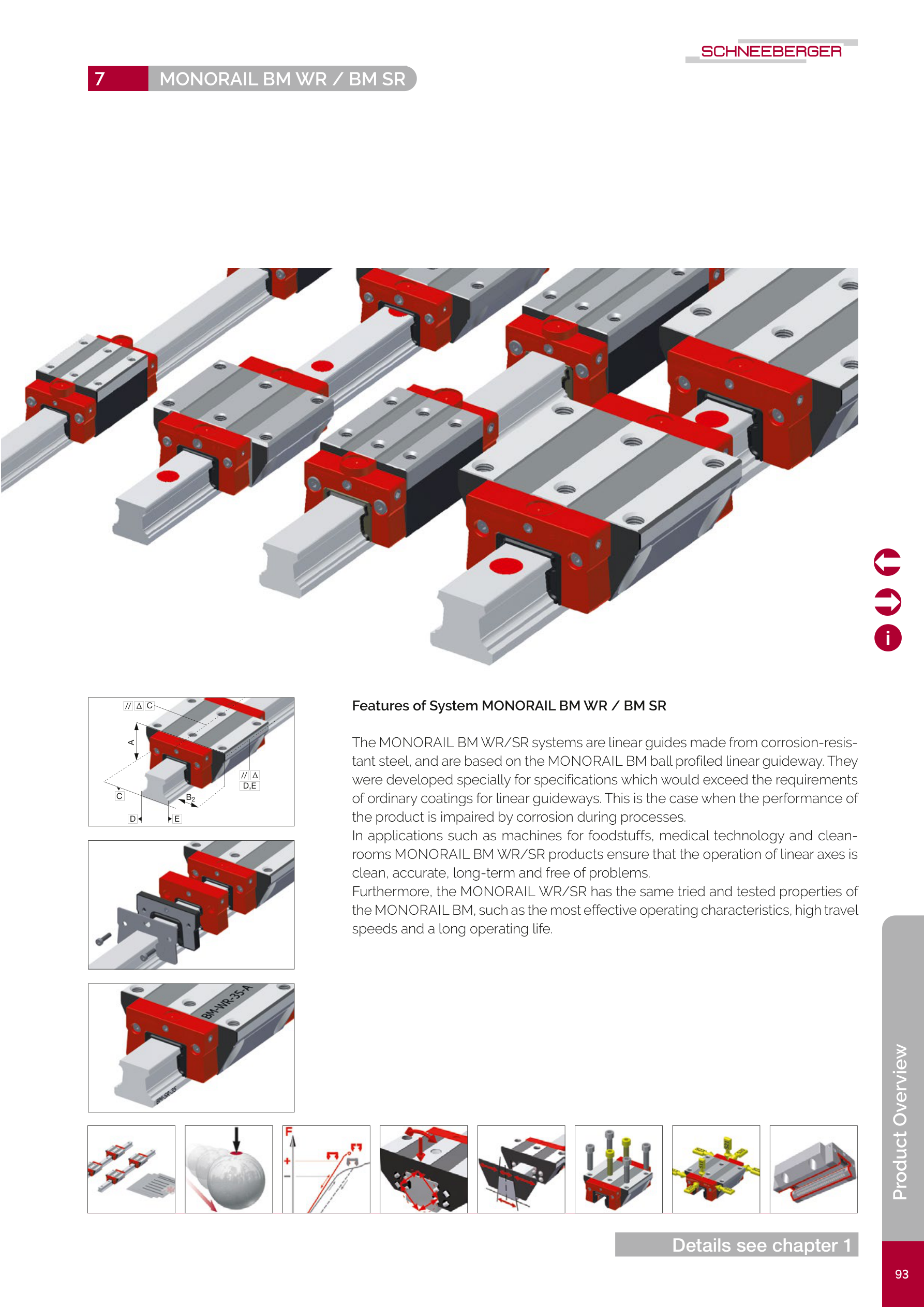

MONORAIL BM WR/SR is SCHNEEBERGER's ball-type linear guide system specifically designed for corrosive environments. This series combines stainless steel rails (SR) with HARTCOAT-coated carriages (WR) to provide excellent corrosion protection, suitable for food processing, medical equipment, pharmaceutical machinery, and cleanroom applications where hygiene and corrosion resistance are critical.

System Nomenclature

- BM SR = Stainless Steel Rail (Stainless Rail) - Provides the highest level of corrosion resistance

- BM WR = HARTCOAT-coated Carriage (Wear Resistant Carriage) - Cost-effective corrosion-resistant solution

The BM WR/SR system features the same trapezoidal rail profile design as the standard BM series, ensuring high system rigidity. Stainless steel rails (BM SR) can be combined with HARTCOAT carriages (BM WR), providing flexible configuration options and excellent cost-effectiveness.

System Components

BM SR - Stainless Steel Rail

- Made of stainless steel, fully hardened

- Highest level of corrosion resistance

- Salt spray test exceeds 1000 hours

- Complies with food-grade safety standards

- Suitable for cleanroom environments (ISO Class 4)

Rail Types (2 types):

- ND = Standard type, top mounting, fully hardened

- NUD = Bottom tapped hole type, fully hardened

BM WR - HARTCOAT Carriage

- Features HARTCOAT special anti-corrosion coating

- Excellent chemical corrosion resistance

- Passes 500-hour salt spray test

- More cost-effective than full stainless steel carriages

- Compatible with standard or food-grade lubricants

Carriage Types (by size):

- A, B = Standard / Standard Long

- C, D = Compact High / Compact High Long

- F, G = Compact (selected sizes)

Product Overview

BM WR/SR System Features

- Excellent Corrosion Resistance - Stainless steel rails exceed 1000-hour salt spray test, HARTCOAT carriages pass 500 hours

- Food-Grade Certified - With food-grade lubricants, complies with FDA and EU food contact regulations

- Cleanroom Compatible - Suitable for ISO Class 4 (Class 10) cleanroom environments

- Low Friction High Speed - Continues BM series advantages, max speed up to 5 m/s

- Trapezoidal Rail Profile - Ensures extremely high system rigidity and stable guidance accuracy

- Flexible Configuration - BM SR rails can be paired with BM WR carriages, optimizing cost and performance

- Full Size Range - Available in five sizes from Size 15 to Size 35

Size Specifications Overview

The BM WR/SR series offers five sizes from Size 15 to Size 35. Below is a comparison of main specifications for each size (load data based on BM SR stainless steel version):

| Size | Rail Width B1 (mm) | Rail Height J1 (mm) | System Height A (mm) | C0 Static Load (N) | C100 Dynamic Load (N) | Available Carriage Types |

|---|---|---|---|---|---|---|

| Size 15 | 15 | 15.7 | 24 / 28 | 16,660 ~ 19,465 | 7,650 ~ 9,690 | A, C, F, G |

| Size 20 | 20 | 19 | 30 | 26,690 ~ 34,935 | 12,240 ~ 14,790 | A, B, C, D |

| Size 25 | 23 | 22.7 | 36 / 40 | 39,185 ~ 51,255 | 17,935 ~ 21,675 | A, B, C, D, F |

| Size 30 | 28 | 26 | 42 / 45 | 54,145 ~ 70,805 | 24,820 ~ 30,005 | A, B, C, D, F, G |

| Size 35 | 34 | 29.5 | 48 / 55 | 71,740 ~ 93,755 | 32,895 ~ 39,695 | A, B, C, D |

Note: The load ratings for BM SR stainless steel version are approximately 85% of the standard BM version. BM WR HARTCOAT carriages can be used with BM SR stainless steel rails.

Typical Applications

Food Processing Equipment

Packaging machines, dispensing machines, conveyor systems

Pharmaceutical Equipment

Filling machines, labeling machines, inspection equipment

Medical Equipment

Operating tables, imaging equipment, laboratory instruments

Cleanroom Equipment

Semiconductor, optical, precision assembly

Rail and Carriage Technical Specifications

| Characteristic | BM SR Rail (Stainless Steel) | BM WR Carriage (HARTCOAT) |

|---|---|---|

| Material | Full stainless steel, fully hardened | Steel + HARTCOAT coating |

| Salt Spray Test | 1000+ hours | 500 hours |

| Type Options | ND (Standard), NUD (Bottom tapped hole) | A, B, C, D, F, G (by size) |

| Food Contact | Fully compliant with food-grade standards | Can be used with food-grade lubricants |

| Cleanroom Class | ISO Class 4 (Class 10) | ISO Class 5 (Class 100) |

| Load Capacity | Approximately 85% of standard BM | Same as standard BM carriage |

Note: BM SR stainless steel rails can be combined with BM WR HARTCOAT carriages. This is the most common configuration for this series, balancing corrosion resistance and cost-effectiveness.

Available Sizes

Select a size to view detailed specifications:

BM WR/SR Size 15

Rail width 15mm, smallest size, ideal for miniature precision equipment and light corrosive environments.

View SpecificationsBM WR/SR Size 20

Rail width 20mm, compact design, suitable for small to medium food and pharmaceutical equipment.

View SpecificationsBM WR/SR Size 25

Rail width 23mm, versatile choice balancing size and load capacity.

View SpecificationsBM WR/SR Size 30

Rail width 28mm, mainstream size for medium applications, most complete carriage type selection.

View SpecificationsBM WR/SR Size 35

Rail width 34mm, largest size in WR/SR series, for high-load applications.

View Specifications