1.9.1 Definition

Guideways equipped with rolling bearings produce both airborne noise and structure-borne noise. The airborne noise produced directly by the bearings is secondary. The main noise is structure-borne noise excited by the structure on which the guideway is mounted.

1.9.2 Causes

The main sources of noise generation are elastic deformation at rolling element and guideway contact points, surface conformity, and lubricant effects.

Elastic Deformation

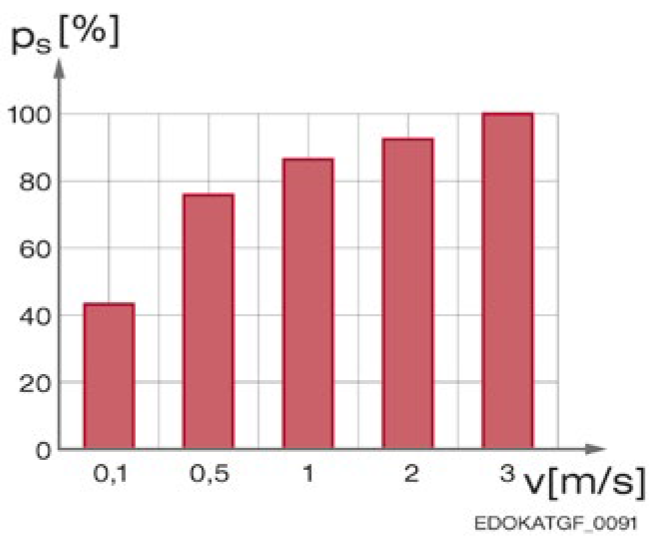

Due to the occurrence of impact-type loads, the contact points between rolling elements and guiding elements undergo deformation. In particular, when rolling elements enter and leave the carriage load zone, periodic oscillations occur, which produce running noise whose intensity and frequency increase with increasing speed.

Sound pressure pS (%) as a function of velocity v (m/s) for ball guideway BM 25 with mineral oil lubrication

Chart description:

X-axis: v [m/s] - Velocity (meters per second)

Y-axis: pS [%] - Sound pressure (percentage)

Trend: Noise level increases significantly with increasing speed

Surface Effects

In addition to elastic deformation, the geometry of rolling contact also has an important influence on running noise. Different diameters of rolling elements, waviness, or surface irregularities all produce noise. These geometric variations cause uneven forces during rolling contact, which in turn cause vibration and noise.

Friction

The friction contact surfaces between rolling elements, between rolling elements and surrounding guiding elements, and between sealing elements all generate structure-borne noise through sliding friction and rolling friction. These friction contacts cause high-frequency vibrations that propagate through the guideway structure and are amplified by surrounding structures.

Lubricant

The lubricating film in the carriage has a noise-dampening effect, as it prevents direct mechanical contact between sliding surfaces and contact surfaces. The lubricating film forms a protective layer between contact surfaces, which can absorb some vibration energy, thereby reducing the noise produced by direct metal-to-metal impact. The thickness and viscosity characteristics of the lubricating film have a direct influence on noise reduction.

1.9.3 Measures to Reduce Noise

Lubricant

The thicker the lubricating film, the less metal contact and noise. Therefore, using special grease is an excellent method for noise reduction. SCHNEEBERGER recommends using NLGI grade 2 mineral oil-based greases with calcium soap or barium soap as thickeners, which can form a stable lubricating film on rolling element contact surfaces.

Proper grease not only reduces running noise but also extends guideway service life and improves running smoothness. The viscosity and thickener type of the grease affect the thickness and stability of the lubricating film, thereby directly affecting noise reduction. Compared to dry running or oil-only lubrication, using high-quality grease can significantly reduce noise levels.

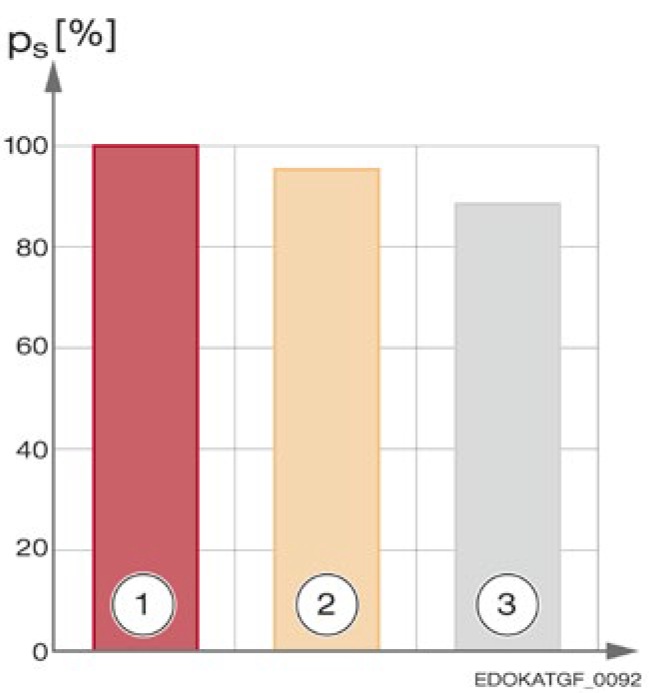

Sound pressure pS (%) as a function of lubrication condition for ball guideway BM 35

Legend:

Y-axis: pS [%] - Sound pressure (percentage relative to dry condition)

Conclusion: Using grease can significantly reduce running noise by approximately 12%

Surface Treatment

To reduce running noise caused by metal contact between rolling elements and surrounding guiding elements, in the case of linear guideways, special attention should be paid to reducing surface roughness of contact surfaces. Smoother surfaces can reduce vibration excitation during contact, thereby reducing noise levels.

Therefore, SCHNEEBERGER not only manufactures roller carriages but also ball carriages with plastic return channels, which helps reduce noise. Plastic return channels, compared to metal channels, can absorb more vibration energy and provide smoother transitions when rolling elements enter and leave the load zone.

Additionally, some carriage designs also include additional lubricant storage reservoirs that can provide continuous lubricant supply to rolling elements, ensuring sufficient lubricating film thickness is maintained throughout operation. This design not only reduces noise but also improves overall running performance.

Spacers

In addition to the effective noise reduction measure of using lubricant, SCHNEEBERGER also offers the option of adding spacers between balls for BM ball guideways. This is a mechanical solution specifically designed to reduce noise.

These spacers prevent rolling elements from rubbing against each other or colliding with each other, thereby eliminating the noise produced by direct contact between balls. Unlike chain systems, the advantage of spacers is that they only bear compressive stress; since there are no connecting rods or connection mechanisms, they do not produce bending stress or tensile stress. This purely compressive loading design makes spacers more durable and does not produce additional noise due to fatigue during high-speed operation.

Another advantage of the spacer system is its simple structure and low maintenance requirements. Compared to chain systems that require regular inspection of connecting rod wear and looseness, the spacer system only requires ensuring that the spacers themselves are not damaged. This design simplifies maintenance work while providing excellent noise reduction performance.

Noise Reduction Recommendations

- Use appropriate lubricant and maintain adequate lubrication

- Select carriages with plastic return channels

- Consider using ball guideways with spacers

- Ensure flatness of installation surfaces