Mineral Casting Material Properties

Mineral casting is a composite material composed of natural mineral aggregates and epoxy resin binder, manufactured using a cold casting process. Compared to steel, gray cast iron, or iron castings, it offers several unique advantages.

Material Advantages

- Excellent damping characteristics

- Low thermal conductivity

- Chemically inert

- Cold casting process

- Low shrinkage rate

- High design freedom

- Integration of multiple mechanical parts

- No waste disposal issues

Design Considerations

- Elastic modulus lower than cast iron

- Requires precision molds

- More sensitive to impact

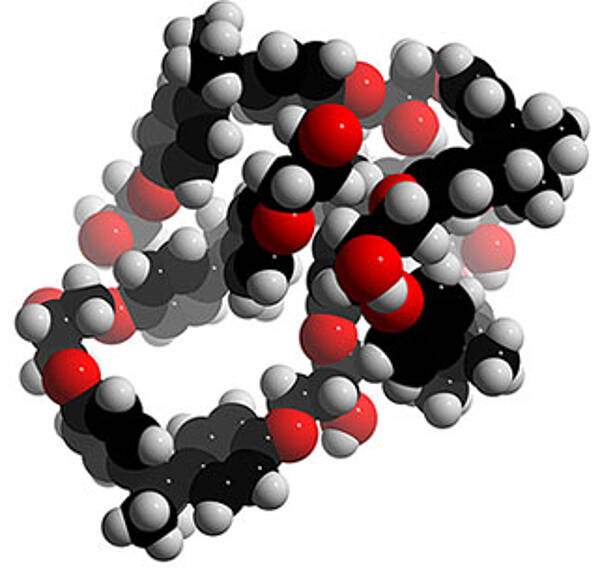

Material Composition

Binder

Primarily uses epoxy resin as binder, providing excellent mechanical properties and chemical stability. The chemical reaction between binder and filler occurs at room temperature (cold casting process). Epoxy-based castings are not suitable for operating temperatures above 80°C.

Filler

Uses high-purity natural quartz rock as filler in various particle size grades. The filler characteristics determine the main properties of the mineral casting, including density, tensile strength, compressive strength, elastic modulus, thermal expansion coefficient, and thermal conductivity.

Standard Mineral Casting Material

Mineral casting material is primarily composed of epoxy resin and quartz aggregate, a homogeneous material manufactured using cold casting process that is durable, non-corrosive, chemically inert, and resistant to most chemicals.

Material Property Parameters

Source: SCHNEEBERGER Mineral Casting Technology

Material Properties and Design Considerations

Elastic Modulus, Density and Strength

The elastic modulus, density, tensile/compressive strength of mineral casting differs significantly from steel and cast iron. Design considerations include:

- Increase wall thickness, calculate deformation, optimize structural stiffness

- Adjust self-weight, calculate modal and frequency, optimize dynamic performance

- Large difference between tensile and compressive strength requires proper design of load direction

Thermal Expansion Coefficient

The thermal expansion coefficient of mineral casting (11.5 - 14×10⁻⁶ K⁻¹) is similar to steel (~12×10⁻⁶ K⁻¹), meaning:

- Contact engagement with steel embedded parts is not affected by thermal forces

- Steel guide rail mounting surfaces maintain good fit accuracy

Thermal Conductivity

Mineral casting has low thermal conductivity (1 - 3 W/m·K), providing these advantages:

- Short-term temperature changes have minimal effect on the structure

- Provides good thermal stability, reduces thermal deformation

- Long aging time, stable long-term precision

Linear Shrinkage

Mineral casting uses cold casting process with excellent shrinkage characteristics:

- Cold casting process, virtually no thermal effects

- Small shrinkage after curing (~0.3‰), ensures basic accuracy

- Only very large castings require thermal compensation during pouring

Millable Layer Material: FS80

FS80 is a specially formulated mineral casting material that can be processed using conventional milling. After pre-casting in the mold, the surface can be milled similar to nylon, with lower cost and no special casting tooling required.

FS80 Features

- Conventional milling process

- Lower cost

- No special casting tooling required

- Nylon-like milling characteristics

SCHQ Series Material Comparison

SCHNEEBERGER offers various quartz-based mineral casting mixtures for different application requirements. All data measured at 20°C.

| Property | SCHQ10 | SCHQ30 | SCHQ40 | SCHQ50 | SCHQ100 |

|---|---|---|---|---|---|

| Density (kg/dm³) | 2.3 | 2.30 | 2.20 | 2.20 | 1.7 |

| Elastic Modulus (kN/mm²) | 42 (38-45) | 40 (35-40) | 33 | 30 (27-32) | 11 (8-13) |

| Compressive Strength (N/mm²) | 110 (>80) | 110 (>80) | 110 (>80) | 110 (>80) | 110 (>100) |

| Tensile Strength (N/mm²) | 13 (>10) | 15 (>12) | 16 (>12) | 17 (>13) | — |

| Poisson's Ratio | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 |

| Damping Ratio | 0.3% | 0.4% | 0.5% | 0.6% | 0.8% |

| Thermal Expansion (10⁻⁶/K) | 16 | 19 | 19 | 19 | 35 |

| Thermal Conductivity (W/m·K) | 3 | 3 | 3 | 3 | 1 |

| Specific Heat (kJ/kg·K) | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 |

| Linear Shrinkage (mm/m) | 0.3 | 0.3 | 0.3 | 0.3 | — |

| Minimum Wall Thickness (mm) | 80 | 60 | 40 | 20 | 5-10 |

| Max. Aggregate Size (mm) | 16 | 12 | 8 | 4 | — |

Source: SCHNEEBERGER Technical Data Sheets 542 400 056-060

techcon® Ultra-High Performance Concrete

techcon® is an ultra-high performance concrete with high quartz content, produced using cold casting process. An economical alternative to standard mineral casting, suitable for cost-sensitive applications requiring mineral casting advantages.

| Property | Value | Unit |

|---|---|---|

| Density | 2.3 - 2.4 | kg/dm³ |

| Elastic Modulus | 48 | kN/mm² |

| Compressive Strength | 130 - 140 | N/mm² |

| Tensile Strength | 4 - 6 | N/mm² |

| Thermal Expansion | 12×10⁻⁶ | K⁻¹ |

| Thermal Conductivity | 2 - 4 | W/(m·K) |

| Linear Shrinkage | 0.7 | mm/m |

| Minimum Wall Thickness | 40 | mm |

| Max. Aggregate Size | 4 | mm |

Source: SCHNEEBERGER Technical Data Sheet 542 400 970

Material Selection Guide

SCHQ10

General High Stiffness

Suitable for machine parts with high stiffness requirements that are easy to refill. Also suitable for filling welded steel structures, gray cast iron, and other parts.

SCHQ30

Medium Wall Thickness

Same applications as SCHQ10 but allows thinner wall designs.

SCHQ40

Thin Wall Design

Suitable for thin-wall machine parts such as brackets and frames. Excellent damping characteristics.

SCHQ50

Ultra-Thin Wall Design

Suitable for ultra-thin wall machine parts using small casting methods.

SCHQ100

Precision Surface Coating

Precision casting mixture for sealing cast surfaces, suitable for outer layer coating applications.

FS80

Millable Layer Material

Specially formulated for conventional milling, lower cost without special casting tooling.

techcon®

Economical Alternative

Ultra-high performance concrete, suitable for cost-sensitive applications. Highest compressive strength and stiffness.

Vibration Damping Characteristics

Vibration damping is one of the most significant advantages of mineral casting, directly affecting machining accuracy and speed.

Practical Benefits: Up to 10x vibration damping means higher machining speeds, better surface quality, and longer tool life.

Material Certification

Material properties compiled by SCHNEEBERGER in cooperation with inspire AG and research institutions at ETH Zurich, tested by authorized laboratories.

Disclaimer: Material recommendations are based on years of experience and current knowledge. Suitability testing is the customer's responsibility; supplier assumes no related liability.