Efficiency

Efficiency

The natural rolling resistance in the contact areas of rolling elements is an unavoidable loss. Therefore, the actual efficiency ηa is always slightly less than 100%.

Transformation of a torque into an axial force

Transformation of an axial force into a back torque

Factors Determining the Angle of Friction

Factors Determining the Angle of Friction

Manufacturer's Specific Features

- Form of ball tracks - Track geometry of screw and nut

- Manufacturing accuracy - Level of machining precision

- Surface hardness - Hardness of screw and nut

- Surface quality - Surface treatment of ball tracks

- Recirculating system - Ball return design

Users' Operation Data

- Axial load and acceleration - Applied forces and dynamic conditions

- Lubrication - Lubricant type and condition

- Number of rotation - Operating speed

- Mounting accuracy - Alignment of screw and nut

Practical Efficiency and Operating Temperature

Practical Efficiency and Operating Temperature

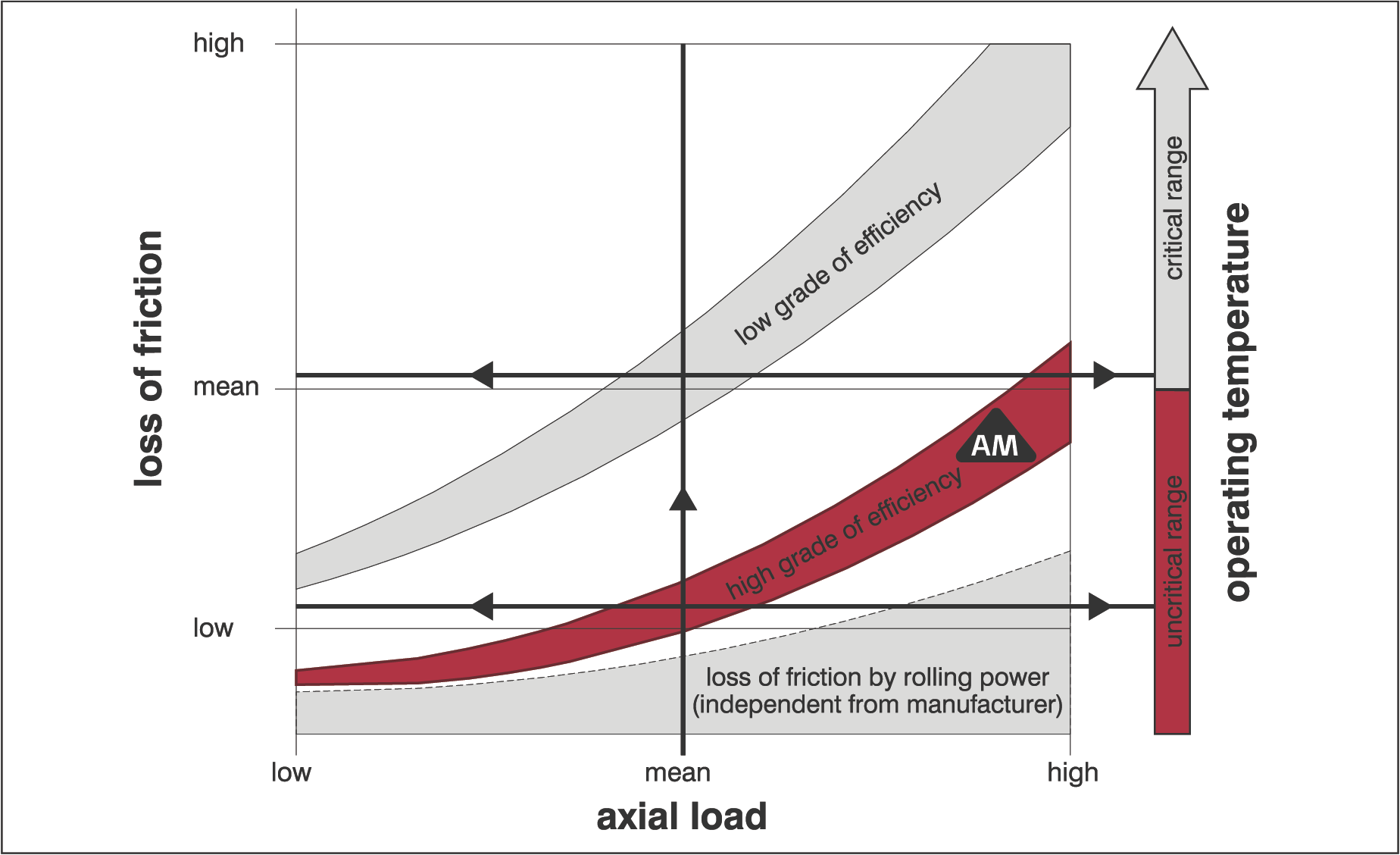

Under operating conditions, the axial load Fa may be several times the nut preload Fpr. Therefore, the manufacturer's specific features have a significant impact on the actual efficiency ηa. The effect of efficiency on operating temperature can be seen from the chart.

Angle of Friction for AM Ball Screws

After adjusting nut preload and the resulting axial rigidity, the angle of friction ρ for AM ball screws is approximately 0.2 degrees

Effect of efficiency on operating temperature

Driving Torque

Driving Torque

Transformation of a torque Ma into an axial force Fa

Transformation of an axial force Fa into a back torque Me