2.1.1 Construction

Linear guideways with integrated BZ 25 and BZ 35 rack drive consist of a BM profiled rail guideway with integrated rack, on which one or more rolling element carriages run, as well as one or more drive pinions that mesh with the rack. All BM type carriages can be used with the corresponding size guideways.

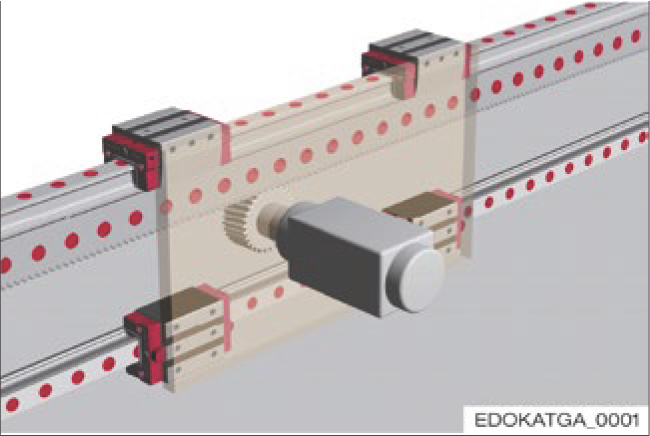

Typical application areas for this type of system include handling, automation, waterjet/laser cutting systems, woodworking, etc. To construct a complete axis system, a standard BM SCHNEEBERGER MONORAIL guideway is typically used as a parallel rail. The pinion is usually driven by a gear motor (see figure), which is not part of SCHNEEBERGER's scope of supply.

Parallel rail with pinion

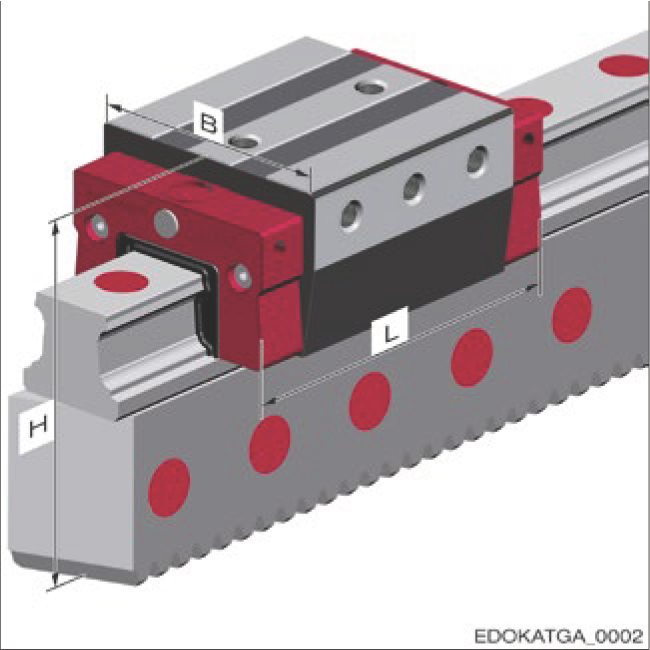

The rack is fixed to the underside of the guideway, ensuring that no directional alignment is required between the rack and guideway.

Additionally, for SCHNEEBERGER MONORAIL guideways with integrated MONORAIL BZ type rack drive, the AMS 4B distance measuring system can also be integrated.

Carriage with guide rail and rack

BZ guideways can be butt-jointed together.

2.1.2 Integration Advantages

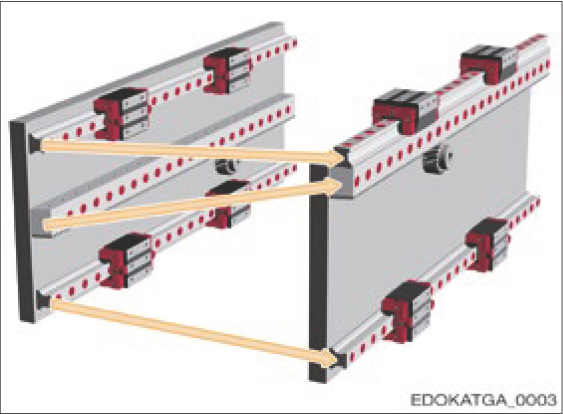

Integrating the rack drive into the SCHNEEBERGER MONORAIL guideway offers significant advantages over separately installed racks:

Integration of rack drive into SCHNEEBERGER MONORAIL guideway

- Reduced design and manufacturing costs, as only two positioning surfaces are required for guiding and driving, rather than three

- Minimized space requirements due to the compact design

- No need to install and position rack segments in the machine

- No need for rack directional alignment to guideway

- Reduced logistics overhead

- No need to purchase and store racks

- Only one supplier for guiding and driving

2.1.3 Comparison with Other Drive Designs

Advantages of BZ SCHNEEBERGER rack drive compared to other drive methods:

Compared to Ball Screws

- Multiple independent motions can be achieved on a single guiding system

- Significantly higher rigidity at long lengths and high forces (backlash)

- Positioning is not affected by temperature

- Interchangeable in some cases

- Significantly more robust and durable

- Design does not limit speed capability (similar to spindle tilt)

- Preload is fully adjustable and can be varied during operation

- No vibration tendency at long lengths

- No separate storage required

- Unlimited stroke distances can be achieved

Compared to Toothed Belt Drives

- Significantly higher forces can be transmitted

- More precise positioning and higher rigidity under alternating forces

- Less wear

- Temperature resistance

- Teeth will not break

Compared to Linear Motors

- Significantly lower investment

- Significantly lighter

- No cooling required

- Significantly higher forces can be transmitted

- Does not attract metal debris (such as chips)

- Smaller guideways can be selected as no additional magnetic attraction force needs to be considered

- No brake required for carriage when power is off

- Significantly lower energy costs

- "Elastic" response to alternating forces

2.1.4 Gear Quality

The gear quality of spur gears is defined in DIN 3961/3962/3963/3967 and tested according to DIN 3999. The tolerance grade (e.g., quality grade 5, Q5) determines the dimensional accuracy of the rack (pitch error, form and position tolerances, reference circle deviation, profile deviation from nominal, etc.), thus affecting the positioning accuracy and running quality achievable by the rack drive.

Quality grade 5 (depending on manufacturer) is the highest grade that can be manufactured using cost-effective grinding engineering. Since the specified standard only applies to gears, all information about racks is interpreted as a pinion with z = 100 teeth.

SCHNEEBERGER offers two gear qualities for the MONORAIL BZ system to meet different customer requirements for quality and cost-effectiveness:

Pinions available as accessories (see SCHNEEBERGER MONORAIL and AMS product catalog) are quality Q6 and are basically hardened and ground, because pinion teeth engage significantly more times per travel distance than rack teeth.

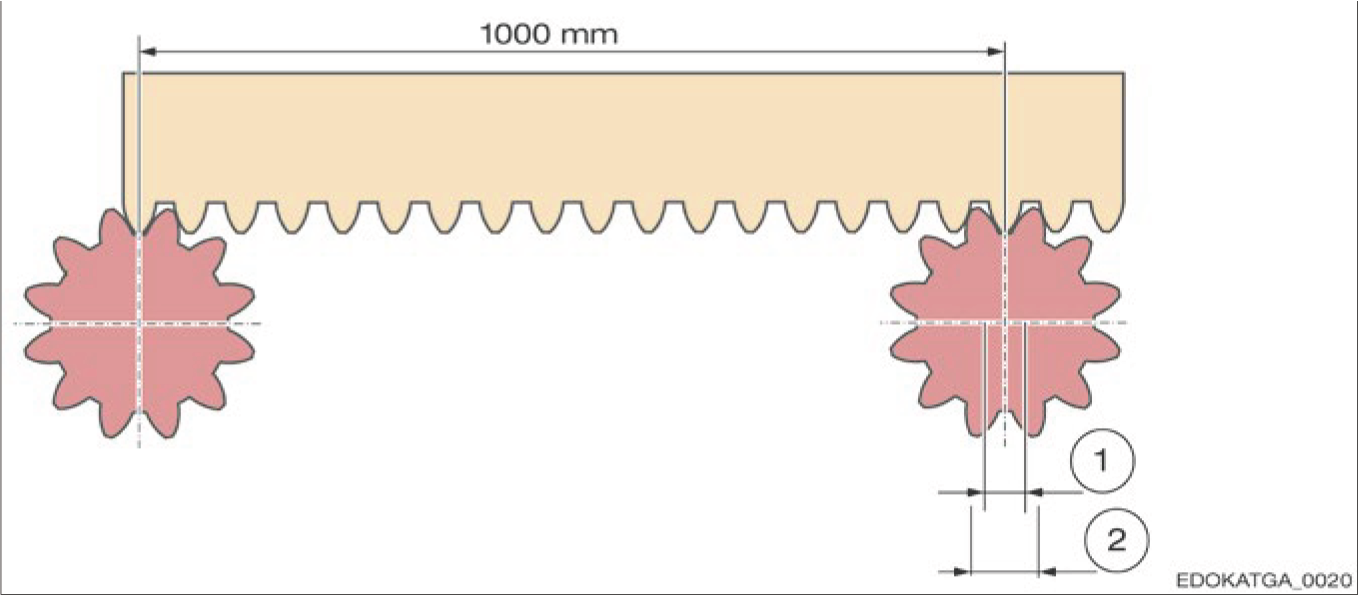

Example for 1000 mm travel distance for tolerance Q5 and Q6

Cumulative pitch error example for 1000 mm travel distance:

- Q5 cumulative pitch error ≤ 40 µm (available on request)

- Q6 cumulative pitch error ≤ 50 µm