AXRY-NGS bearings are double-direction, screw-on precision bearing units ready for installation, designed for applications demanding both high rigidity and high-speed performance, such as mill-turn tables or vertical lathes.

These bearings absorb axial and radial forces plus tilting moments without backlash.

AXRY-NGS bearings optimize speed, rigidity, and service life within spatial constraints. For achieving limiting speeds with extended duty cycles, circulating oil cooling on both inner and outer rings is recommended. Bearings are delivered with standard grease pre-lubrication. Oil lubrication, oil channels, and oil-air minimum quantity lubrication are available on request.

! Attention!

Three essential criteria for functional high-speed axis operation:

- Cooling

- Lubrication

- Temperature Monitoring

Generation AXRY-NGS

The myonic NGS generation bearings have been continuously optimized and further developed from the AXRY-EX series, featuring numerous improvements:

- Enhanced stiffness values

- Enhanced load ratings

- Extended service life

- Elevated limiting speeds with extended duty cycles

- Axial and radial lubrication via outer ring

- Optional: Radial lubrication via inner ring (-SBI)

- Particularly quiet operation

- Reduced thermal development

- Integrated temperature sensor bore on outer ring

- Cooling channels can be designed directly on inner ring

Of course, for NGS bearings, all variant options are available, including tighter radial and axial runout tolerances, tighter height tolerances H1/H2, and customer-specific bearing adjustments.

Generation AXRY-NGS-SBI

The NGS-SBI generation myonic bearings have the same functionality as the NGS series but have been dimensionally optimized for high-speed outer ring rotation, serving as the successor to the AXRY-OS series. NGS-SBI features include the following improvements:

- Enhanced stiffness values

- Enhanced load ratings

- Extended service life

- Elevated limiting speeds with extended duty cycles

- Radial lubrication via inner ring

- Particularly quiet operation

- Reduced thermal development

- Integrated temperature sensor bore on inner ring

For the AXRY-NGS-SBI series, all variant options are available, including tighter radial and axial runout tolerances, tighter height tolerances H1/H2, and customer-specific bearing adjustments.

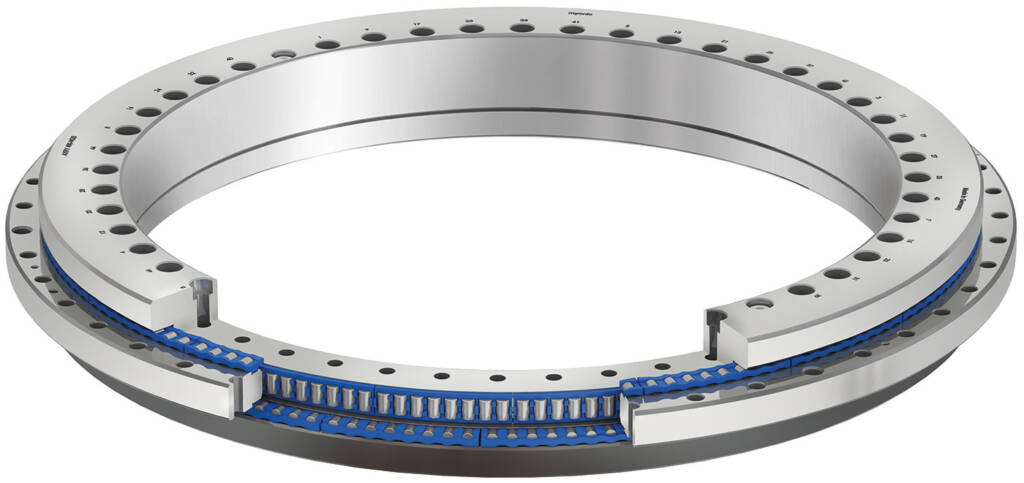

Bearing Structure

AXRY-NGS (NGS-SBI) bearings comprise three rings: inner ring, outer ring, and axial washer. The inner ring bore is manufactured with fit tolerance.

The axial washer remains unsupported near the bore area, centered to the inner ring and secured with fastening screws.

Fastening Screws

The fully assembled bearing is held together with fastening screws. The axial washer is factory-aligned to the inner ring.

If the fastening screws must be removed, they can only be replaced after the bearing is completely bolted. If fastening screws are removed beforehand, the axial washer must be realigned to prevent system imbalance.

Important Note

When reinstalling after removing fastening screws, ensure proper alignment of the axial washer to the inner ring to prevent system imbalance.

NGS vs NGS-SBI Comparison

| Feature | AXRY-NGS | AXRY-NGS-SBI |

|---|---|---|

| Rotation Type | Inner Ring Rotation | Outer Ring Rotation |

| Lubrication Method | Axial/radial lubrication via outer ring | Radial lubrication via inner ring |

| Temperature Sensor Bore | Outer Ring | Inner Ring |

| Predecessor Series | AXRY-EX | AXRY-OS |

| Typical Applications | Mill-turn tables, vertical lathes | High-speed outer ring rotation applications |

Next Steps

Learn more about AXRY-NGS bearing technical details:

- Bearing Features - Accuracy requirements, lubrication variants, temperature monitoring

- Static Load Diagrams - Static limiting load diagrams for all sizes

- Adjacent Construction Design - Design principles and accuracy requirements