Parallelism of Reference and Locating Surfaces

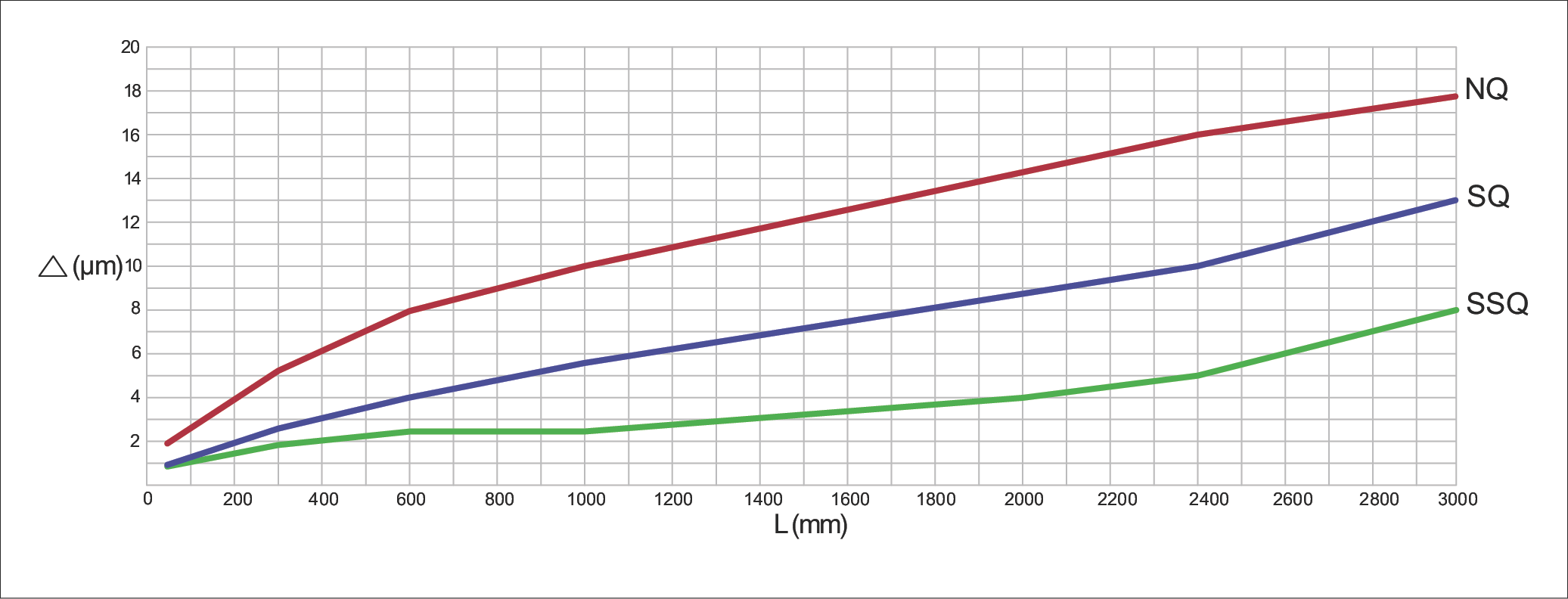

They must be compatible with the linear guideways (also applicable to linear guideways using recirculating units):

| NQ | Normal quality |

| SQ | Special quality |

| SSQ | Super special quality |

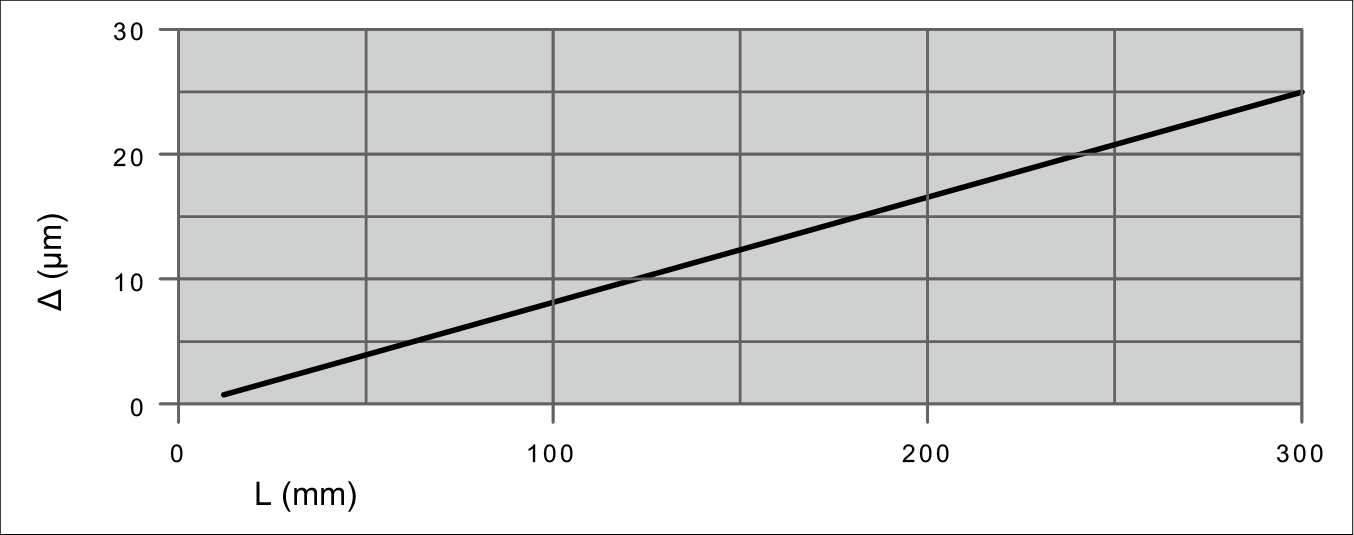

Parallelism deviation Δ (µm) vs guideway length L (mm) relationship curves

Surface Quality

The precision of application strictly determines the required surface quality of reference and locating surfaces.

- For high-precision applications, they must show a maximum Ra value of 0.4

- Standard applications must not exceed Ra value 1.6

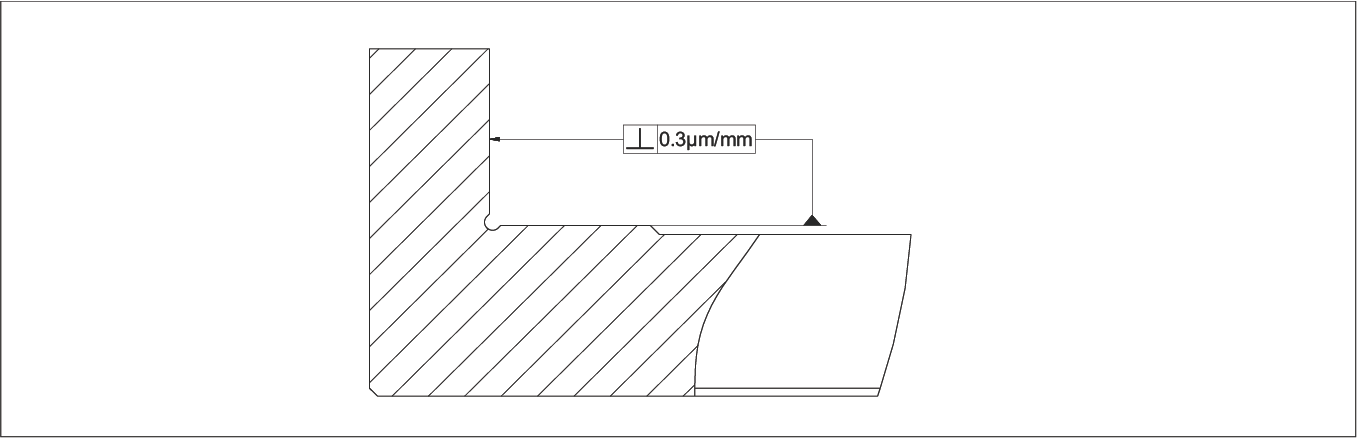

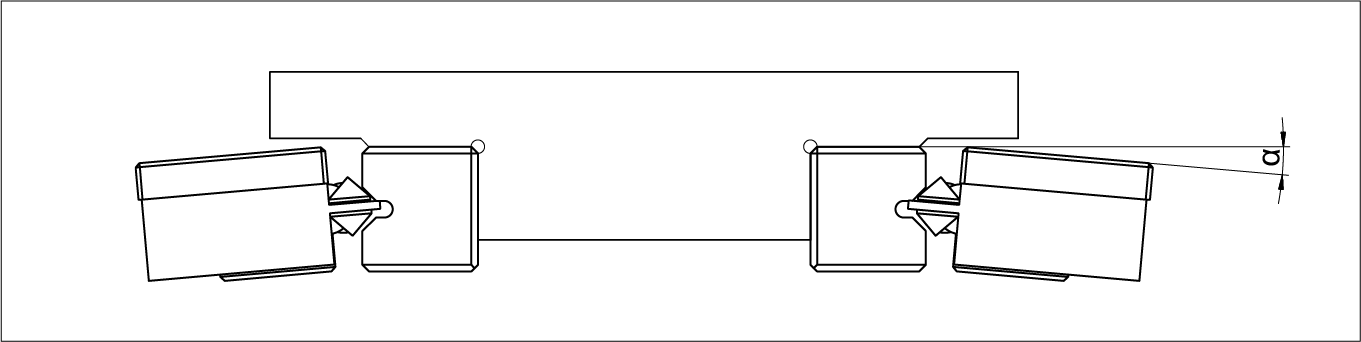

Angular Error

The angular error of the support and locating surfaces should not exceed 0.3 µm/mm.

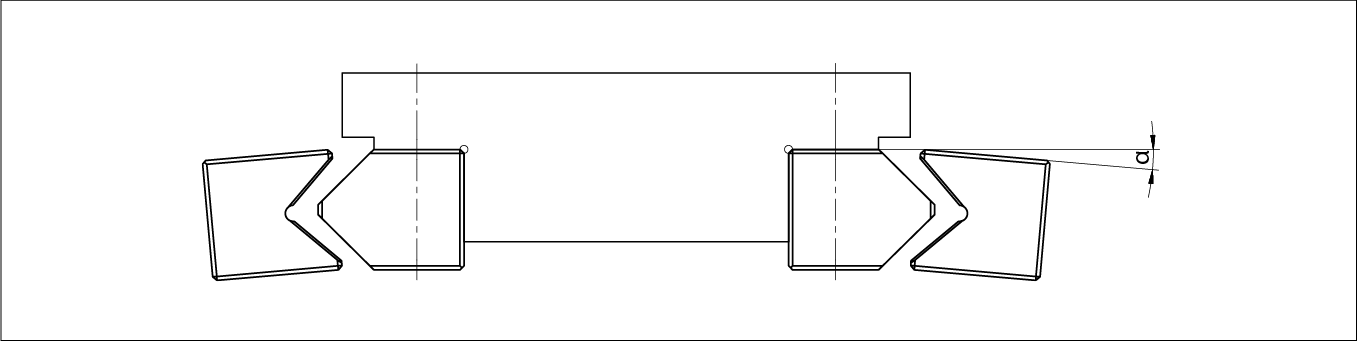

Height Offset for Linear Guideways

Angular errors caused by height offset and/or elastic deformation must not exceed the following values:

| Balls or rollers | 0.3 µm/mm |

| Needles | 0.1 µm/mm |

Parallelism of Support and Locating Surfaces for Recirculating Units

The parallelism of the support and locating surfaces relative to the mating track can be derived from the following diagram:

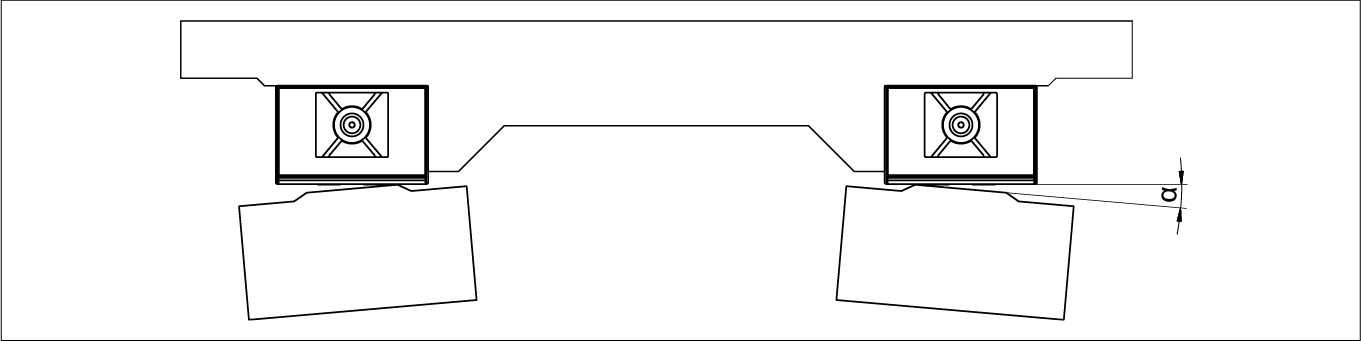

Height Offset for Recirculating Units

Angular errors caused by height offset and/or elastic deformation must not exceed the following values:

| Type SK, SKD and SKC | 3.0 µm/mm |

| Type SR | 0.3 µm/mm |

| Type NRT | 0.3 µm/mm |

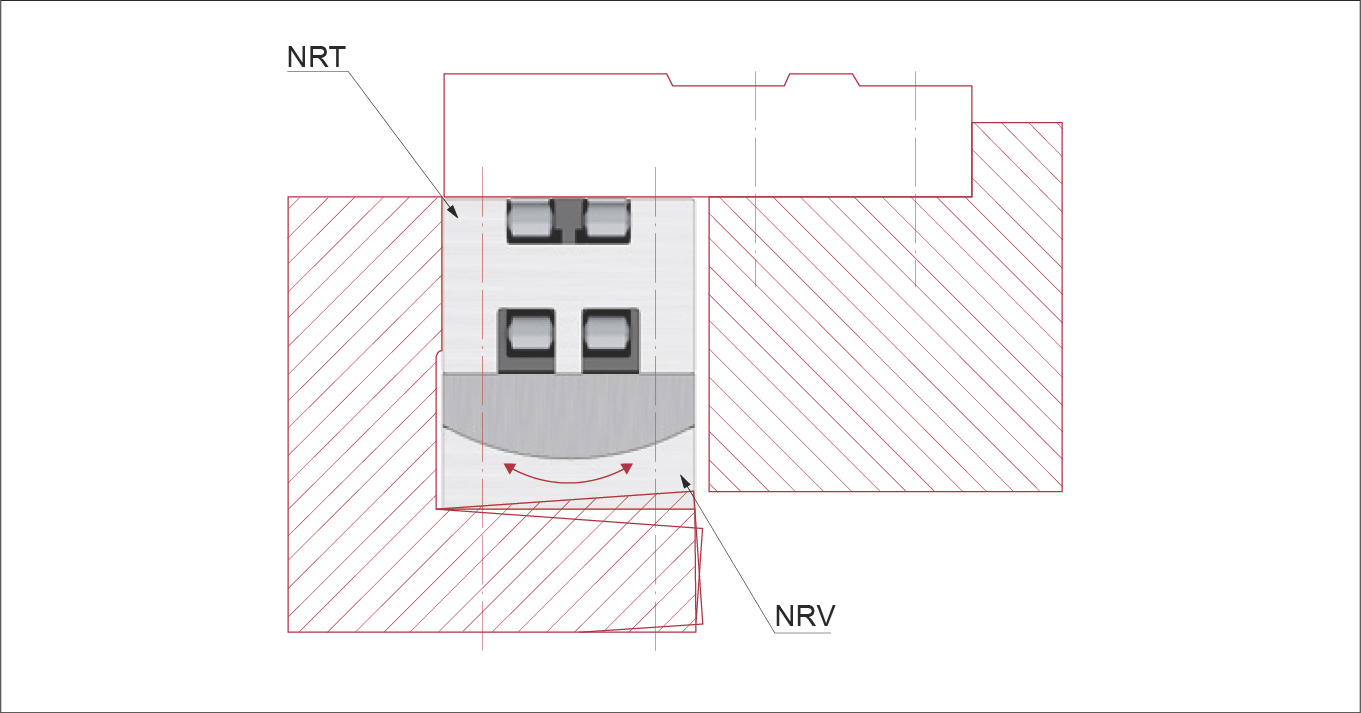

Combination of Recirculating Unit NRT with Preload Wedge NRV

To guarantee straight running, the recirculating unit NRT must always be aligned against the locating surface.

The preload wedge NRV should be aligned opposite to the recirculating unit and compensate for angular errors.