Lubrication is a critical design element that must be defined during the development phase of the machine or application. Selecting lubrication based solely on experience after design and construction is complete can lead to significant difficulties. A well-thought-out lubrication concept is a hallmark of modern and carefully engineered design.

Parameters to consider when selecting a lubricant include:

- Operating conditions: (speed, acceleration, stroke, load, installation orientation)

- External influences: (temperature, aggressive media or radiation, accumulated contamination, humidity)

- Re-lubrication: (time intervals, quantity, compatibility with other lubricants)

- Compatibility: (with corrosion protection, with integrated materials such as plastic slides)

- Tracks: (geometry, surface roughness, hardness, material, coating, wettability)

Technical and economic factors must be considered when determining the lubricant and process. Lithium soap-based rolling bearing greases are commonly used (particularly alloy greases conforming to DIN 51502 or DIN 51825 KP2K). Oil distributors or occasional oiling through oil nipples can meet guideway requirements. For minimal rolling friction resistance, mineral oil-based lubricating oils are recommended (CLP or HLP with ISO VG 15 to 100 viscosity conforming to DIN 51519).

Lubricant is typically applied through the gap between linear guideways and recirculating units, or through lubrication holes (standard or lubrication nipples in recirculating units). If the design does not support this method (e.g., vertical installation), linear guideways with lubrication holes can be provided upon request. Oil mist lubrication methods are particularly advantageous for preventing contamination accumulation due to slight overpressure, but their acceptability is limited due to environmental impact. It is recommended to keep cutting oils or water-soluble coolants away from guideways as they can dilute or wash away lubricant, and coolants adhere when dried. Lubricants containing solid additives are not suitable.

Re-lubrication Intervals

Re-lubrication intervals depend on the operating conditions and external influences mentioned above and cannot be precisely calculated. Therefore, lubrication points must be observed over an extended period.

Historical experience shows that under normal use conditions, 2 to 5 re-lubrications at most are sufficient within the calculated service life.

Lubrication of NRT Recirculating Units

There are three ways to lubricate NRT.

| Method | Description |

|---|---|

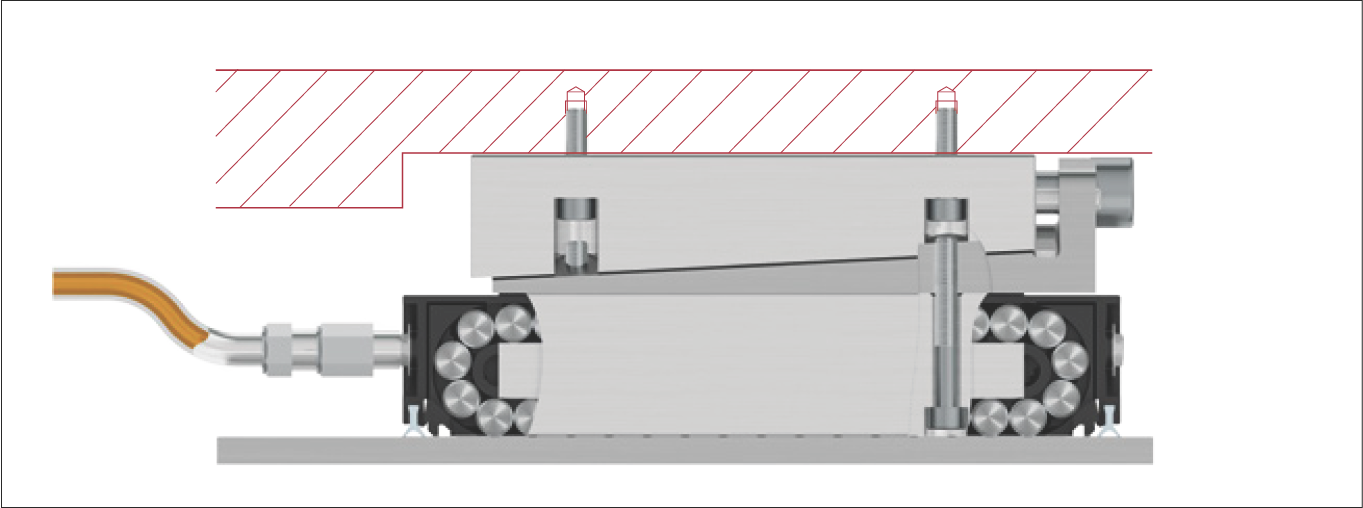

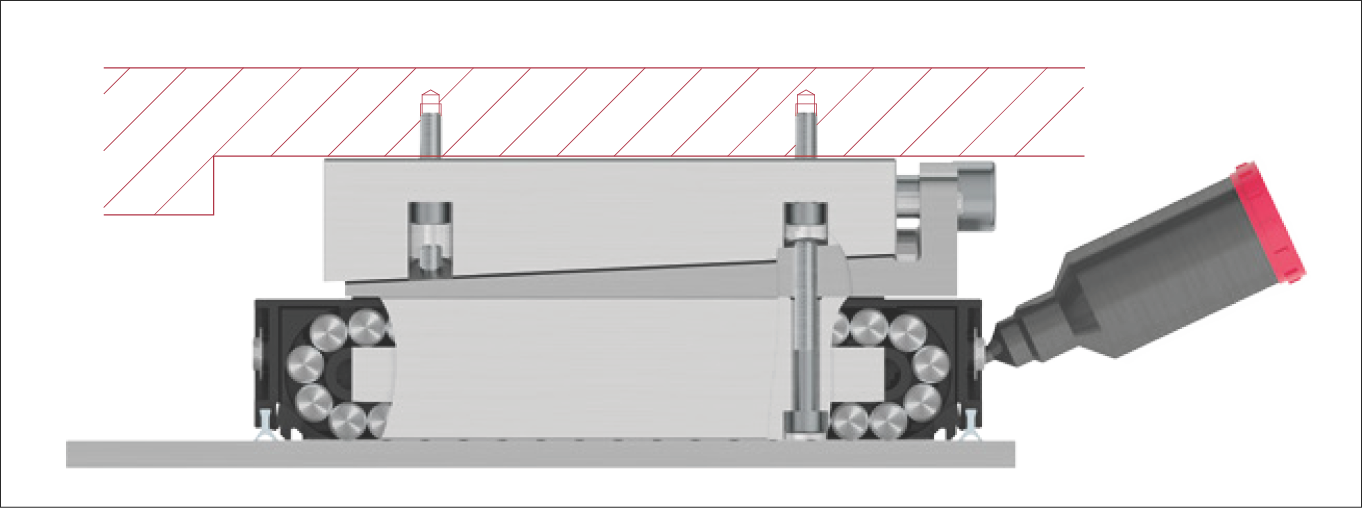

| Method A: | Lubrication nipple on each end face |

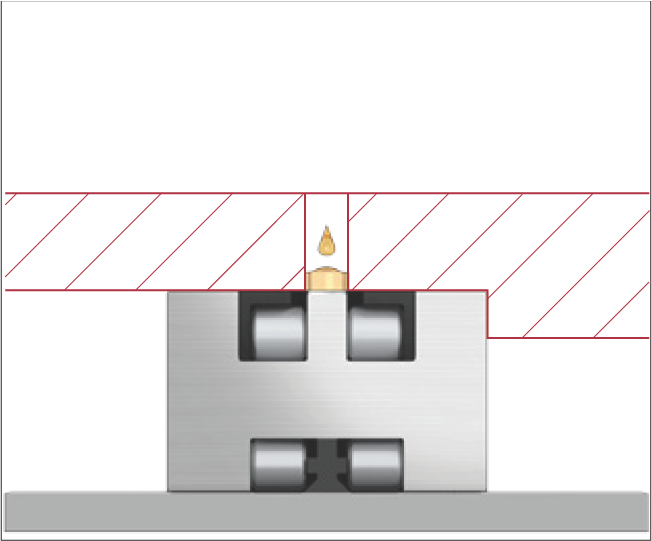

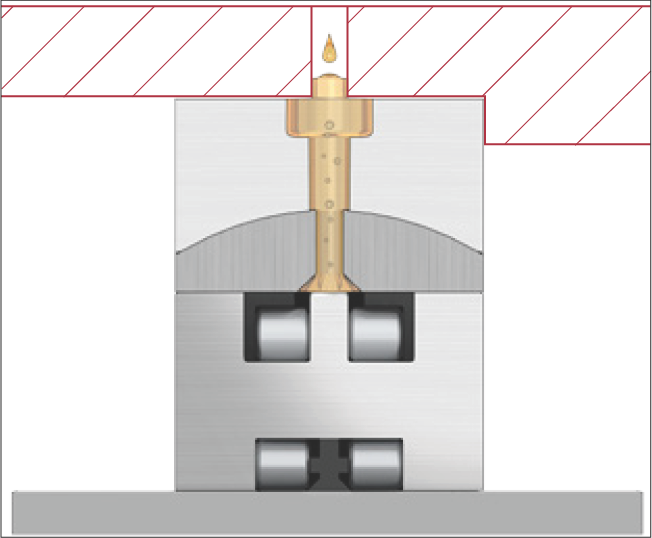

| Method B: | Lubrication hole at the top |

| Method C: | Optional connection for centralized lubrication system |

Method A: Lubrication via Lubrication Nipple

Method B:

Oil supply through top lubrication hole

Oil supply through top lubrication hole of preload wedge NRV

Method C: Centralized Lubrication System (Option ZS)