Hipp Miniature Ballscrews - Ballscrew Technology

Ballscrew Technology - Terminology Glossary

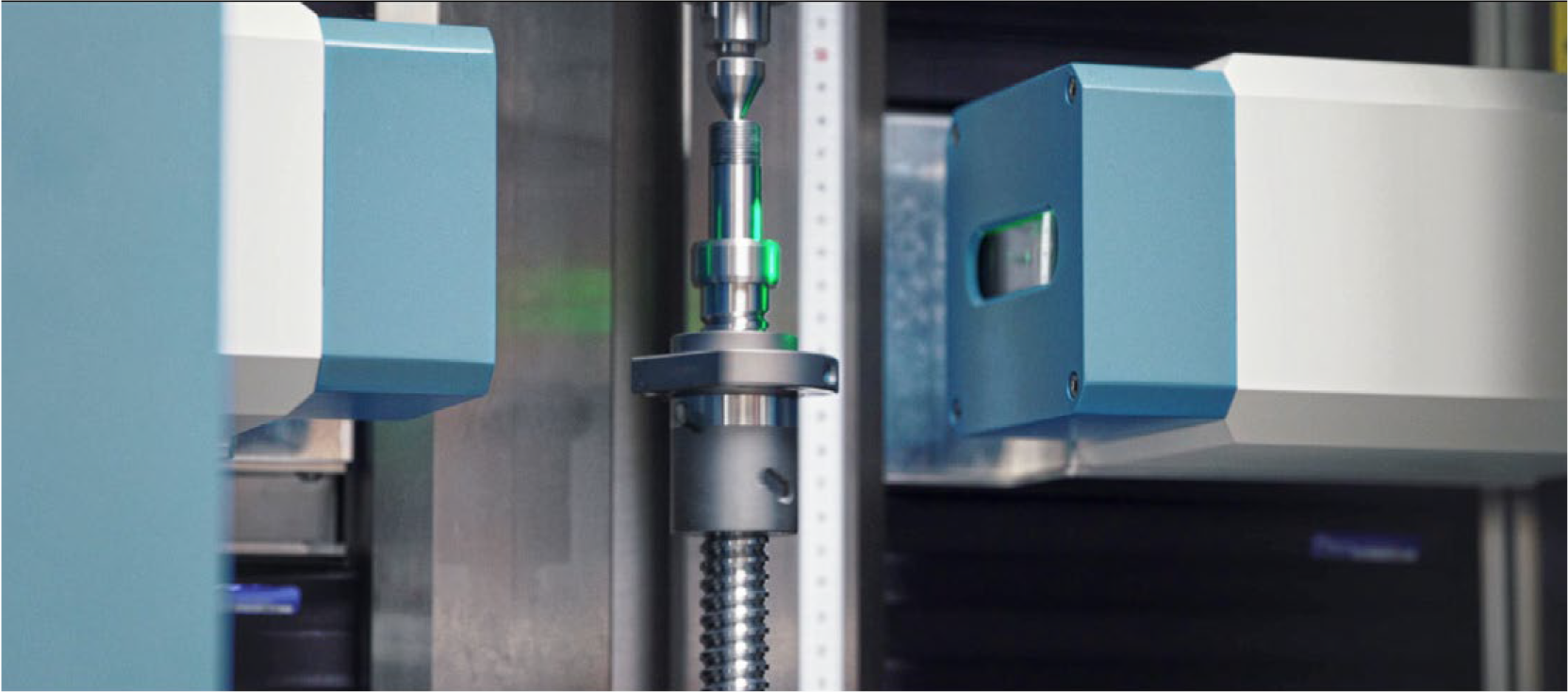

Ballscrews for the Highest Demands

The various demands of mechanical engineering, measurement technology, and medical technology require linear drives of the highest precision. Hipp precision ground ballscrews are designed for exactly these requirements. Whether in production robots or surgical microscopes, our ballscrews enable precise and fast linear motion. Our developers will also develop appropriate solutions for your special requirements.

General Information

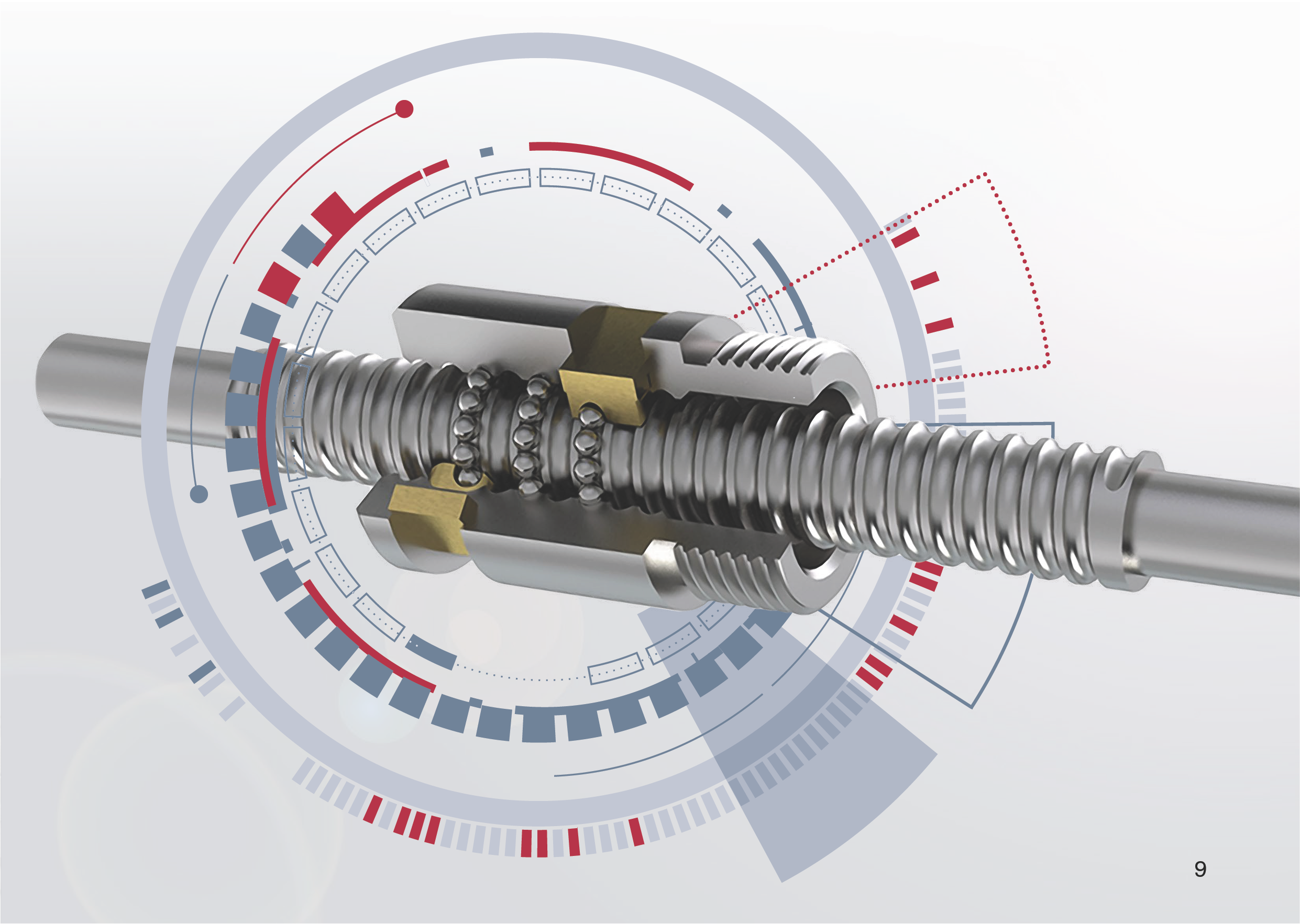

Ballscrews convert rotary motion into linear motion. The balls are the rolling elements between the ballscrew spindle and nut. The dynamic and positioning accuracy of a ballscrew depends primarily on the production precision and the technical implementation of the specified tolerances.

Advantages of Ballscrews over Lead Screws

- Significantly longer service life

- Very high travel speeds

- Low heat generation

- No stick-slip effect

- Very high positioning accuracy

- Very high efficiency

- Lower required input power

- No axial play with proper preload

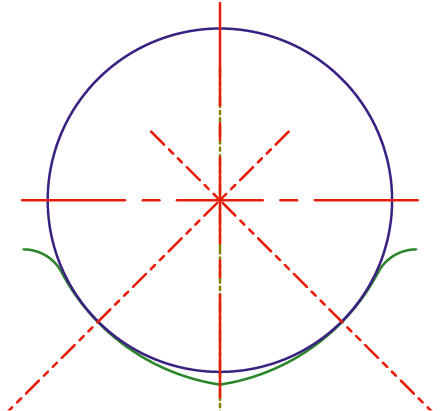

Thread Profile

Our ballscrews use a "Gothic arch" raceway profile. The optimal relationship between ball diameter and raceway radius creates a contact angle of approximately 45° between the spindle and nut. This gives our ballscrews excellent running characteristics under maximum axial load. The ball raceway profiles of all miniature ballscrews are ground using state-of-the-art machinery after heat treatment.

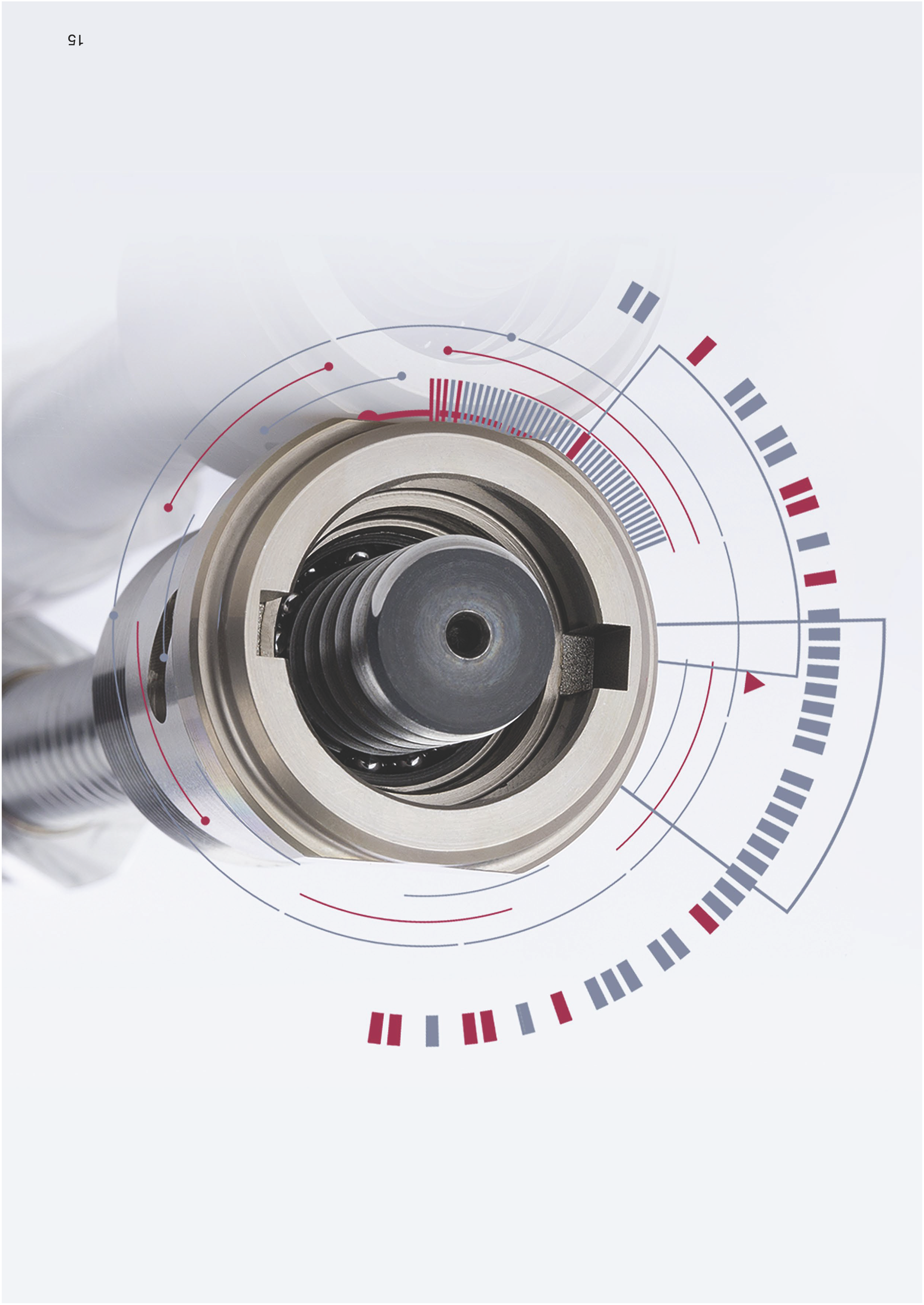

Nut Systems

- Low-play single nut

- Anti-backlash pre-loaded single nut

- Anti-backlash pre-loaded double nut

- Spring pre-loaded double nut in the housing

Pre-loading

Preload force is the axial force within the nut system used to improve positioning accuracy. Because our ballscrews are manufactured with extreme precision, preloading using a four-point system is possible as standard. This gives us optimal ratings.

Materials

We use the following materials as standard:

| Component | Material | Hardness |

|---|---|---|

| Ballscrew spindle | Cf53 | Ball raceway hardened to 60 ±2 HRC |

| Ballscrew nut | 100Cr6 | Hardened to 60 ±2 HRC |

| Balls | 100Cr6 | Hardened to 60 ±2 HRC |

Stainless Steel Version (on request)

- Ballscrew spindle: 1.4112 - Ball raceway hardened to 56 ±2 HRC

- Ballscrew nut: 1.4034 - Hardened to 56 ±2 HRC

- Balls: 1.4034 - Hardened to 56 ±2 HRC

- Note: Cstat and Cdyn are reduced by approximately 20% for stainless steel versions

Tolerance Classes

Karl Hipp GmbH ballscrews are manufactured according to DIN ISO 3408, in tolerance classes 1 to 10. The tolerance classes and tolerances for the effective stroke lu conform to ISO/DIS 286/1.

| Measuring length [mm] | IT1 [µm] | IT3 [µm] | IT5 [µm] | IT7 [µm] |

|---|---|---|---|---|

| – 315 | 6 | 12 | 23 | 52 |

| 316 – 400 | 7 | 13 | 25 | 57 |

| 401 – 500 | 8 | 15 | 27 | 63 |

| 501 – 630 | 9 | 16 | 30 | 70 |

| 631 – 800 | 10 | 18 | 35 | 80 |

| 801 – 1000 | 11 | 21 | 40 | 90 |

| 1001 – 1250 | 13 | 24 | 46 | 105 |

| 1251 – 1600 | 15 | 29 | 54 | 125 |

| 1601 – 2000 | 18 | 35 | 65 | 150 |

| 2001 – 2500 | 22 | 41 | 77 | 175 |

| 2501 – 3150 | 26 | 50 | 93 | 210 |

Tolerances conform to DIN ISO 3408-3

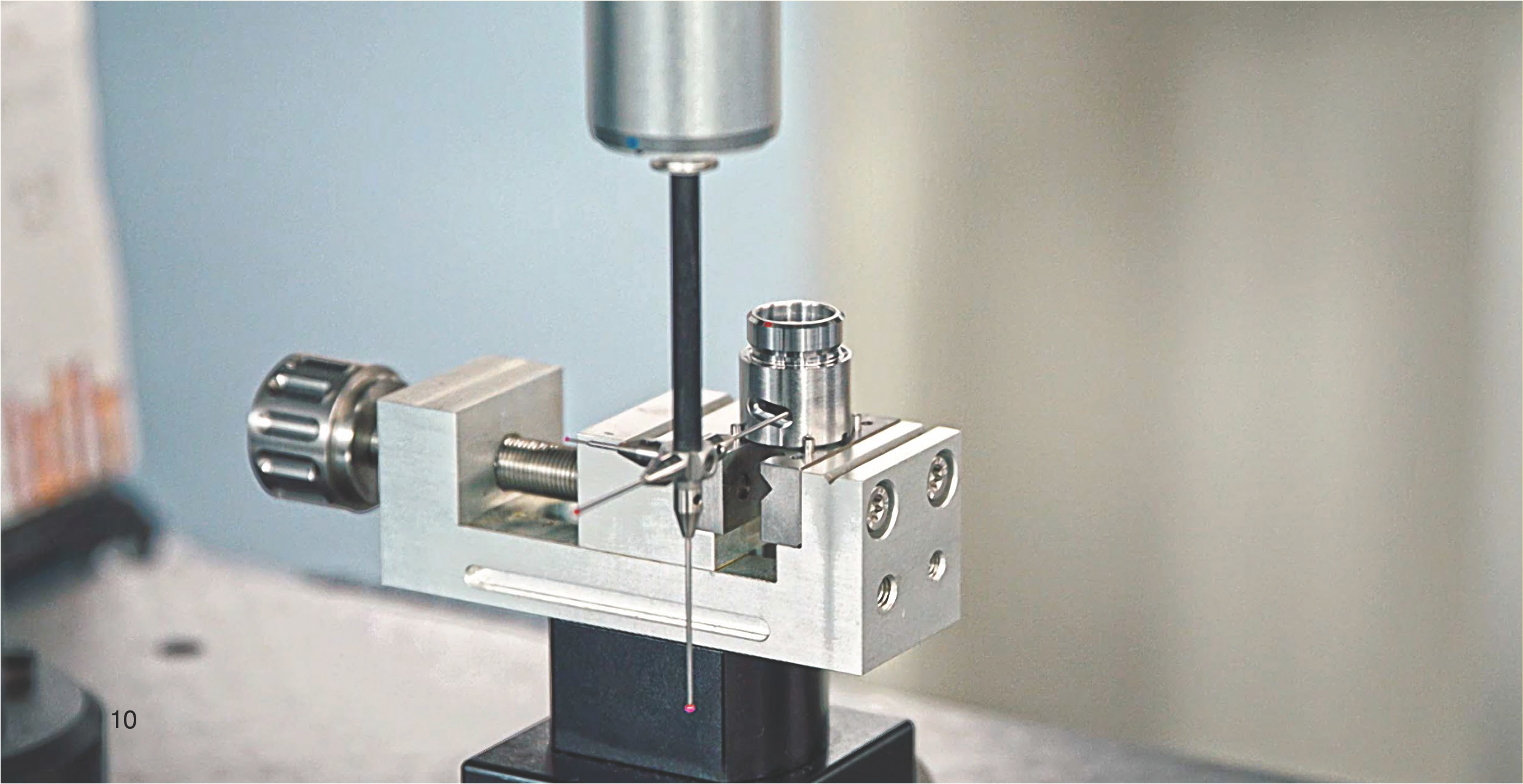

Quality

Karl Hipp GmbH has been certified to DIN ISO 9001 since 1997. All ballscrews are inspected using state-of-the-art measuring and testing machines and coded accordingly.

The following test reports are available on request:

- Lead accuracy

- Form and position tolerances

- Dimensional tolerances

Efficiency

We distinguish between theoretical efficiency and actual efficiency. The actual efficiency and friction coefficient depend on the following factors: lubrication conditions.

Efficiency Calculation Formulas

The following formulas are used to calculate a ballscrew's efficiency:

Lead Angle Calculation

tan α = P / (do · π)

Where: α = lead angle [°], P = lead [mm], do = ball pitch circle diameter [mm]

When Converting Torque to Longitudinal Force

η = tan α / tan (α + ρ)

Where: ρ = friction angle [°], approximately 0.2° to 0.35°

When Converting Longitudinal Force to Torque

η' = tan (α - ρ) / tan α

Actual Efficiency Calculation

ηρ = η · 0.9

0.9 is an average value for load, speed, and lubrication.

Rigidity

The rigidity of a ballscrew affects its geometric and positional accuracy. In our miniature ballscrews, we use zero-play single nuts with four-point preload to achieve very good rigidity values.

Static Rating

The static rating is the coaxially acting axial load corresponding to a total permanent deformation of the ball or ball raceway at the point of maximum stress contact not exceeding 0.0001 × ball diameter. The static rating is reduced by approximately 20% for stainless steel versions.

Dynamic Rating

The dynamic rating is the coaxial axial load at which the ballscrew can achieve a nominal life of 10 million revolutions. The dynamic rating is reduced by approximately 20% for stainless steel versions.

Radial Loads

Radial loads may arise due to installation tolerances but should be kept below 5% of the minimum axial load.

Speeds

When designing ballscrews, attention should be paid to the critical bending speed - at which the spindle resonates - and the maximum speed, both of which largely depend on the nut design and the type of ball recirculation system used.

Guidelines for Maximum Speeds [1/min]

| Lead [mm] | 4 mm | 6 mm | 8 mm | 10 mm | 12 mm | 16 mm | 20 mm | 25 mm | 32 mm | 40 mm |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 4,000 | - | - | - | - | - | - | - | - | - |

| 1 | 4,500 | 4,500 | 3,200 | - | 1,800 | - | - | - | - | - |

| 2 | - | 4,500 | 4,200 | 4,000 | 3,400 | 3,000 | - | - | - | - |

| 2.5 | - | - | 4,200 | - | 3,400 | 3,000 | - | - | - | - |

| 3 | - | - | - | - | 3,400 | - | - | - | - | - |

| 4 | - | - | 4,200 | - | 3,600 | 4,000 | - | - | - | - |

| 5 | - | - | 4,000 | - | 3,600 | 4,200 | 4,000 | 3,800 | 3,500 | 2,700 |

| 10 | - | - | - | - | 3,600 | 4,200 | 4,000 | 3,800 | 3,500 | 3,000 |

Lifetime

Lifetime (nominal life) is expressed as the number of revolutions, i.e., the number of revolutions that 90% of a sufficiently large number of ballscrews reach or exceed before the first signs of material fatigue appear. This number is expressed in revolutions or hours.

Lifetime Calculation Formula

L = (C / Fm)3 × 106

Where: L = lifetime (revolutions), C = dynamic load rating, Fm = mean axial load (N)

Mean Axial Load Calculation

Fm = [(F13 · L1 + F23 · L2 + F33 · L3 + ...) / (L1 + L2 + L3 + ...)]1/3

Where: F = axial load (N), L = load stroke (mm)

Lubrication

Basically, lubricants used for ball bearings can also be used for lubricating ballscrews. Generally, a single lifetime lubrication of the ballscrew is not sufficient, as the ballscrew spindle continuously carries away grease despite the use of appropriate wipers. If possible, appropriate maintenance intervals should be observed. The choice of lubricant depends on several factors. The most important factors are spindle speed, operating temperature, and ballscrew load.

Assembly Specifications

No radial or eccentric forces should be applied to the nut system during installation. Parallelism and perpendicularity deviations should not exceed 0.02 mm.

Wiper

Various types of wipers are available to protect the ballscrew from dirt and contamination, such as felt or plastic.

Operating Temperature

The allowable operating temperature range for ballscrews is -20 °C to +80 °C.