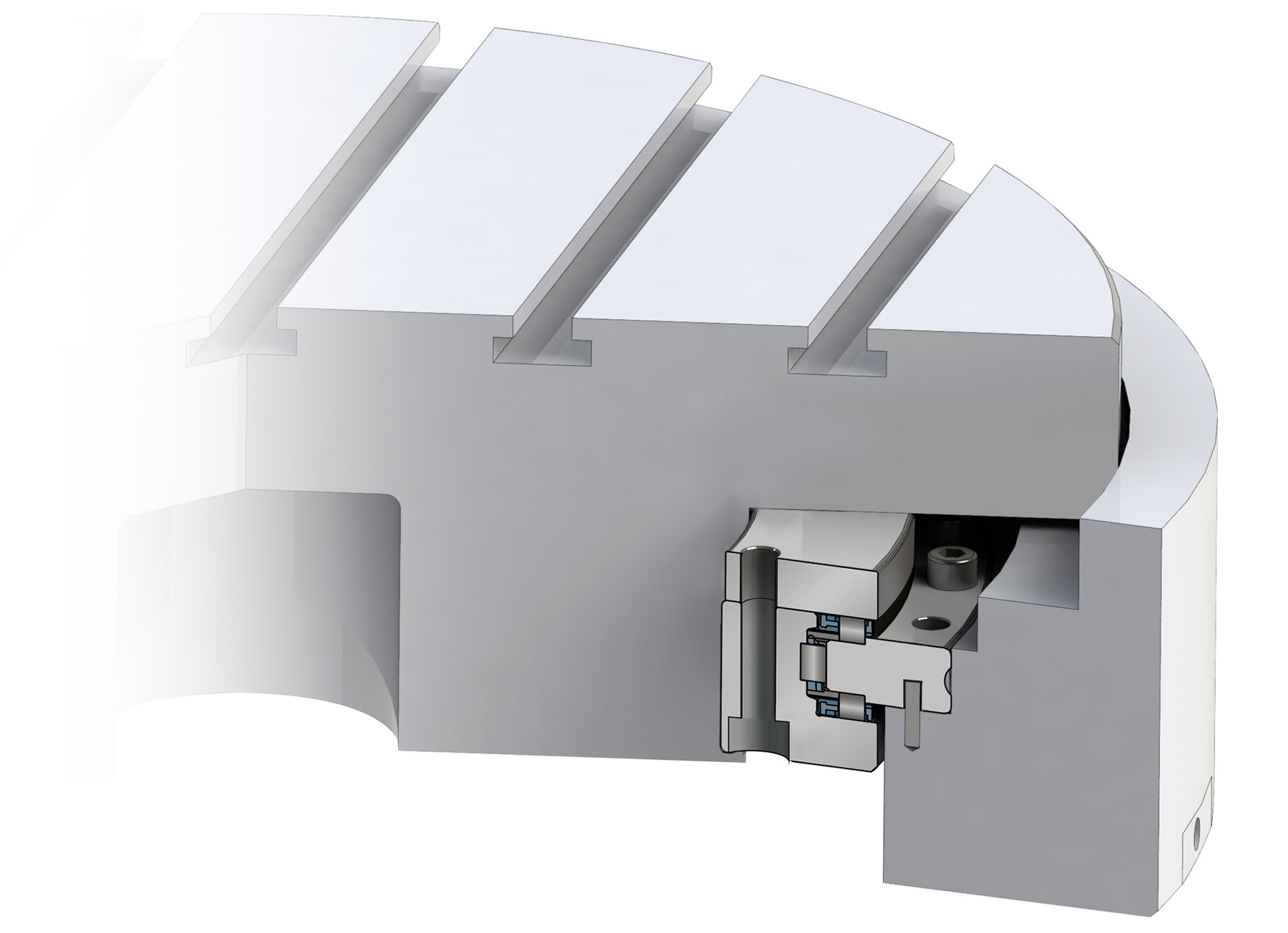

Locating Pin Hole Function

To correctly align the bearing lubrication bore with the machine housing lubrication bore, AXRY-NGS bearings are equipped with a locating pin hole on the outer ring. This ensures precise alignment of the lubrication bore with the housing lubrication channel during assembly.

Positioning Hole Arrangement

The relative positions of the positioning hole and other holes are as follows:

| Mark | Description |

|---|---|

| 1 | Positioning hole |

| 2 | Lubrication bore |

| 3 | Fixing hole |

| 4 | Fastening screw |

Position Relationships

- Positioning hole (1) is offset from fixing hole (3) by half pitch division

- Positioning hole (1) is offset from lubrication bore (2) by one full pitch division

- Positioning hole diameter is slightly larger than the recommended locating pin diameter to ensure proper fit

Note: For detailed pitch division of each bearing model, please refer to the product data sheet.

Locating Pin Dimension Specifications

The following are locating pin specifications for each size series:

| Bearing Model | Pin Height hmax [mm] | Pin Diameter dST [mm] | Positioning Hole dPB min [mm] |

|---|---|---|---|

| AXRY 120 ~ 460-NGS (-SBI) | 4 | 4 | 5 |

| AXRY 580-NGS (-SBI) | 6 | 6 | 8 |

| AXRY 650-NGS (-SBI) | 8 | 8 | 10 |

Dimension Symbol Legend

- hmax - Maximum locating pin height

- dST - Locating pin diameter

- dPB min - Minimum positioning hole diameter

Assembly Requirements

Important Safety Notice

Secure the positioning pins appropriately during assembly. The pins must be reliably prevented from dropping out in operation.

Assembly Steps

- Machine the corresponding positioning hole in the housing (diameter per table above)

- Insert a suitably sized locating pin

- Mount the bearing aligned with the locating pin

- Confirm the lubrication bore aligns with the housing lubrication channel

- Secure the bearing and ensure the locating pin cannot drop out

Lubrication Bore Alignment

Using the locating pin hole ensures:

- Precise alignment of bearing lubrication bore with housing lubrication channel

- Consistent angular position for each assembly

- Correct repositioning after maintenance and reassembly

- Effective lubricant flow to bearing working area

Housing Design Recommendation

The housing lubrication channel should be positioned as close as possible to the bearing's radial lubrication bore to ensure effective lubricant flow into the bearing.

Related Sections

- Bearing Features - Detailed lubrication bore configuration

- Bearing Commissioning - Installation and run-in procedures

- Recommended Fits for Housing - Housing design requirements