General Notes

Fit accuracy and geometrically correct design of all connecting components have a direct influence on the precision requirements and dynamic characteristics of the bearing.

In cases of maximum requirements, tolerances and fits should be restricted accordingly.

Please refer to the structural design notes in the general catalog section.

Surface Roughness Requirements

Ra 0.8 μm - Recommended surface roughness for housing fit surfaces

Stationary Outer Ring

The housing can be designed without fit, or with a G7 fit.

The clearance between the bearing outer diameter and the housing bore makes assembly easier.

Notes for High Dynamic Requirements

For higher dynamic requirements of the rotating shaft (ndm > 35,000 mm/min, long-term operation), a minimum clearance of 20 μm should be maintained between the outer ring and housing.

Rotating Outer Ring

General Requirements

The rotating housing is designed with a J6 clearance fit, which produces a transition fit with a tendency towards clearance fit. The fit surface should be designed over the entire height of the outer ring.

Alternatively, the housing can also be designed with a K5 fit for a tighter fit. This can more easily match the bearing outer diameter tolerance range to meet high requirements; however, assembly may be more complex.

Maximum Accuracy Requirements

For the highest accuracy requirements of rotating outer rings, a 0 μm clearance fit must be targeted; existing clearance fits may increase radial runout. The actual dimension of the bearing outer diameter can be found in the inspection report accompanying all bearings.

High Dynamic Requirements

At higher speeds (ndm > 35,000 mm/min) and longer operating times, interference fit must not exceed 5 μm.

AXCR-U Series Housing Fit Tolerance Table

| Model | Housing Ø Da [mm] | Bearing OD Tolerance Range [mm] | Outer Ring Stationary | Outer Ring Rotating | Rmax [mm] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Housing Tolerance G7 [mm] | T1, T3 [μm] | Housing Tolerance J6 [mm] | Housing Tolerance K5 [mm] | T1 Roundness [μm] | T2 Parallelism [μm] | T3 Perpendicularity [μm] | ||||

| AXCR 80-U | 165 | 0 / -0.013 | +0.054 / +0.014 | 8 | +0.018 / -0.007 | +0.003 / -0.015 | 5 | 2.5 | 5 | 0.1 |

| AXCR 90-U | 210 | 0 / -0.015 | +0.061 / +0.015 | 10 | +0.022 / -0.007 | +0.002 / -0.018 | 7 | 3.5 | 7 | 0.3 |

| AXCR 115-U | 240 | 0 / -0.015 | +0.061 / +0.015 | 10 | +0.022 / -0.007 | +0.002 / -0.018 | 7 | 3.5 | 7 | 0.3 |

| AXCR 160-U | 295 | 0 / -0.018 | +0.069 / +0.017 | 12 | +0.025 / -0.007 | +0.003 / -0.020 | 8 | 4 | 8 | 0.3 |

| AXCR 210-U | 380 | 0 / -0.020 | +0.075 / +0.018 | 13 | +0.029 / -0.007 | +0.003 / -0.022 | 9 | 4.5 | 9 | 0.3 |

| AXCR 270-U | 400 | 0 / -0.020 | +0.075 / +0.018 | 13 | +0.029 / -0.007 | +0.003 / -0.022 | 9 | 4.5 | 9 | 0.3 |

| AXCR 350-U | 540 | 0 / -0.028 | +0.092 / +0.022 | 16 | +0.034 / -0.010 | 0 / -0.032 | 11 | 5.5 | 11 | 0.3 |

| AXCR 360-U | 540 | 0 / -0.028 | +0.092 / +0.022 | 16 | +0.034 / -0.010 | 0 / -0.032 | 11 | 5.5 | 11 | 0.3 |

| AXCR 540-U | 718 | 0 / -0.035 | +0.104 / +0.024 | 18 | +0.038 / -0.012 | 0 / -0.036 | 13 | 6.5 | 13 | 1 |

AXCR-S Series Housing Fit Tolerance Table

| Model | Housing Ø Da [mm] | Bearing OD Tolerance Range [mm] | Outer Ring Stationary | Outer Ring Rotating | Rmax [mm] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Housing Tolerance G7 [mm] | T1, T3 [μm] | Housing Tolerance J6 [mm] | Housing Tolerance K5 [mm] | T1 Roundness [μm] | T2 Parallelism [μm] | T3 Perpendicularity [μm] | ||||

| AXCR 130-S | 205 | 0 / -0.029 | +0.061 / +0.015 | 10 | +0.022 / -0.007 | +0.002 / -0.018 | 7 | 3.5 | 7 | 0.3 |

| AXCR 150-S | 225 | 0 / -0.029 | +0.061 / +0.015 | 10 | +0.022 / -0.007 | +0.002 / -0.018 | 7 | 3.5 | 7 | 0.3 |

| AXCR 180-S | 255 | 0 / -0.032 | +0.069 / +0.017 | 12 | +0.025 / -0.007 | +0.003 / -0.020 | 8 | 4 | 8 | 0.3 |

| AXCR 220-S | 295 | 0 / -0.032 | +0.069 / +0.017 | 12 | +0.025 / -0.007 | +0.003 / -0.020 | 8 | 4 | 8 | 0.3 |

| AXCR 280-S | 355 | 0 / -0.036 | +0.075 / +0.018 | 13 | +0.029 / -0.007 | +0.003 / -0.022 | 9 | 4.5 | 9 | 0.3 |

| AXCR 360-S | 435 | 0 / -0.040 | +0.083 / +0.020 | 15 | +0.033 / -0.007 | +0.002 / -0.025 | 10 | 5 | 10 | 0.3 |

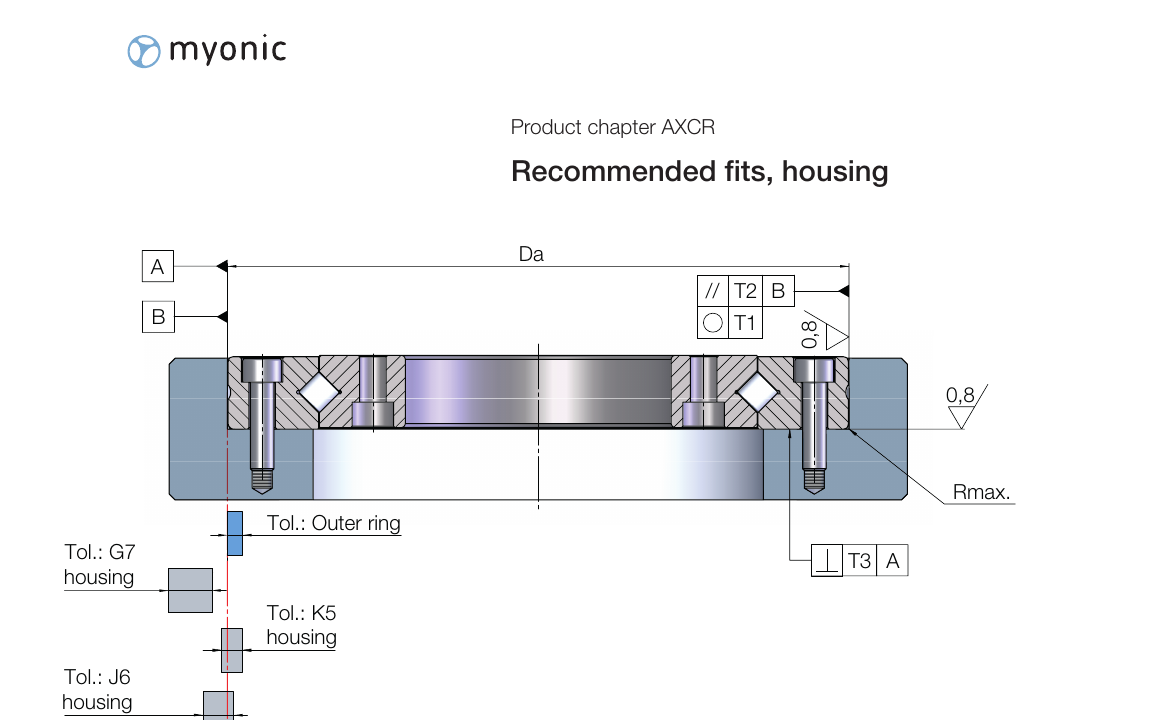

Housing Fit Dimension Diagram

Dimension Symbol Legend

- Da - Bearing OD / housing bore diameter

- T1 - Roundness tolerance

- T2 - Parallelism tolerance

- T3 - Perpendicularity tolerance

- Rmax - Maximum fillet radius

- G7 - Housing tolerance range for stationary outer ring

- J6, K5 - Housing tolerance ranges for rotating outer ring

Notes

Important: Housing Surface Quality

- Surface roughness: Ra ≤ 0.8 μm

- Roundness: According to model requirements (see table above)

- Parallelism: Should be within tolerance range

- Perpendicularity: Perpendicularity of housing bore bottom to housing bore is important

- The above data are recommended values; adjustments may be required based on specific application conditions

- High precision applications may require tighter tolerances

- The housing bore should be clean and free of burrs

- Avoid housing deformation; ensure sufficient housing wall thickness

- myonic AXCR bearing bore and OD are manufactured according to P5/DIN 620 standard with strict tolerance limits