4. Application Examples

MINI-X is suitable for applications where high precision and process reliability are required in space-constrained environments. The unique advantages of MINI-X are fully realized in the following applications:

- Micro-machining

- Biotechnology

- Semiconductor Industry

- Laboratory Automation

- Medical Technology

- Metrology

- Micro-Automation

- Nanotechnology

- Optical Industry

- Robotics

Modern microscopes are indispensable in research and daily medical procedures. To quickly and accurately analyze samples, the slide beneath the lens is constantly moved through a cross table.

Microscope with Scanning Stage

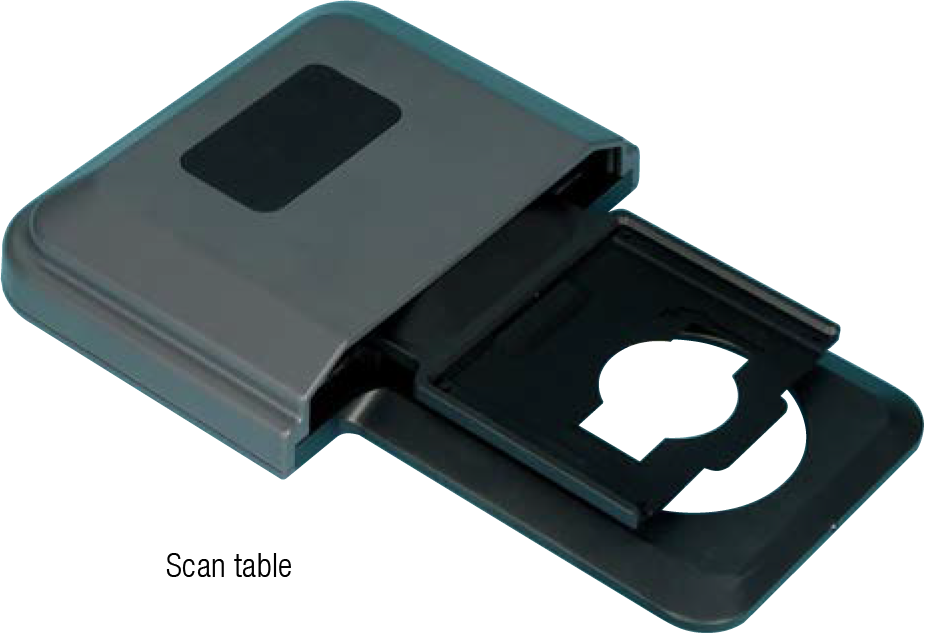

Scanning Stage

The scanning stage shown is based on MINIRAIL and MINISCALE PLUS; the drive is provided by a linear motor. Using these compact components, the weight is reduced by approximately five times compared to conventional construction (ball screw and multi-phase motor). The scanning stage is not only fast but also very quiet. Precision in the smallest areas - repeatable positioning accuracy of a few micrometers.

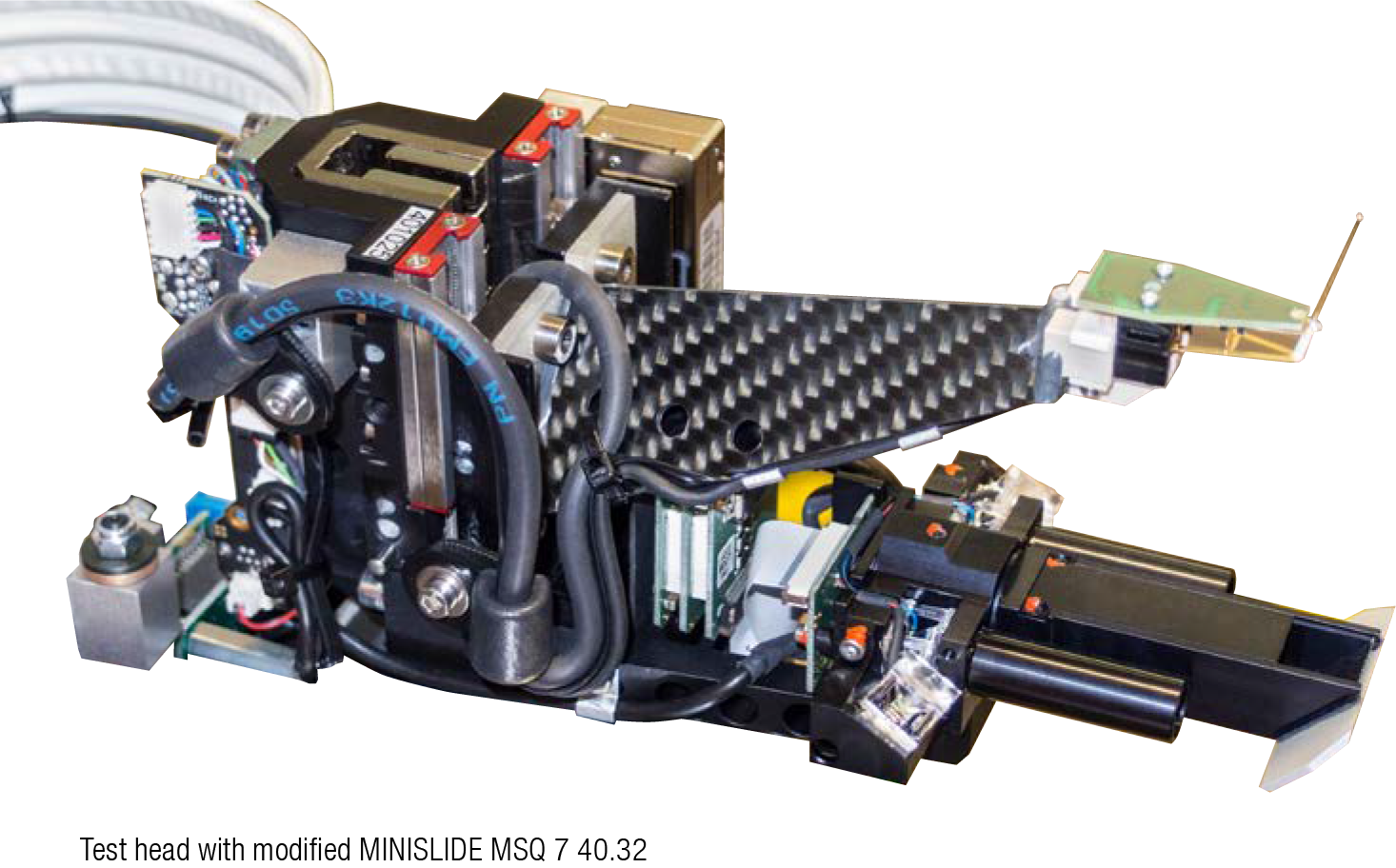

Use of MINISLIDE

For electrical testing where structures measuring only 50 µm or smaller are measured, the precision and speed of the flying probe tester are critical. Especially high accelerations must never affect the contact accuracy of the test design. Manufacturers provide different machine configurations for various products. The latest generation of machines can test an extremely wide range of materials and designs, including rigid and flexible PCBs, as well as everything from IC packages to touch panels.

Flying Probe Test System

- Acceleration: 30 g

- Stroke: 1 – 2 mm

- Total Stroke: 10 – 15 mm

- Repeatability: 1 – 2 µm at working point

- Lubrication: Maintenance-free after initial lubrication

Test Head with Modified MINISLIDE MSQ 7 40.32