Importance of Fit Accuracy

The accuracies of the fits and the geometrically correct design of all connecting parts are decisive for bearing function. Errors in the adjacent construction can substantially increase the friction torque.

The actual bearing bore dimension is provided in the inspection report accompanying each bearing.

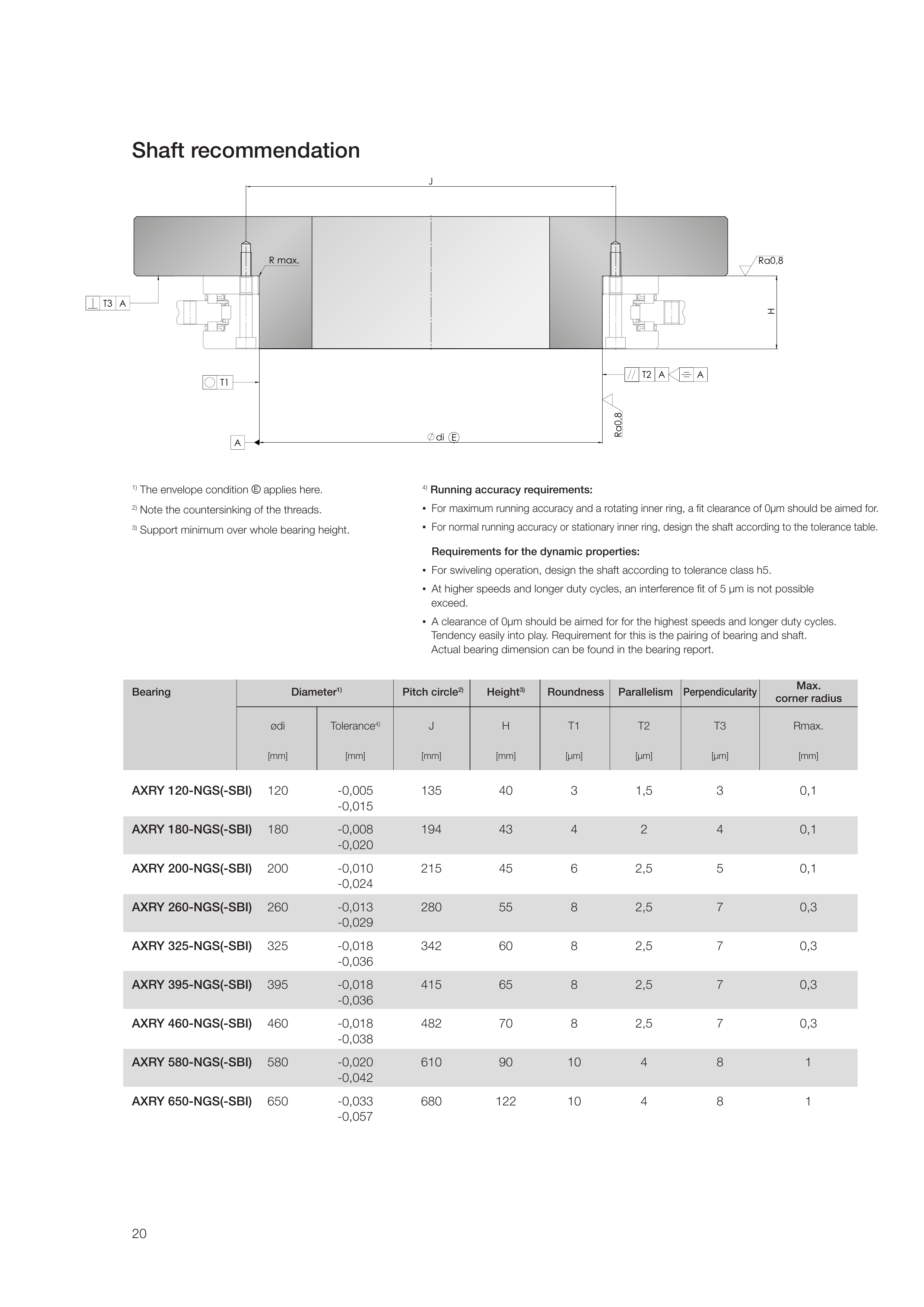

Shaft Dimension Diagram

Design Notes

Important Notes

- Envelope condition applies - Dimensional tolerances include form tolerance requirements

- Countersink for threaded holes - Threaded holes on shaft shoulder require countersinking

- Minimum support requirement - Shaft must provide full surface support across the entire bearing height

- Surface roughness - Ra 0.8 um (mating surfaces)

Inner Ring Rotates (NGS Series)

Design shaft diameter according to the tolerance table specifications below.

High Running Accuracy

For maximum running accuracy, the clearance fit should approach zero. This prevents increasing radial runout.

Accuracy Recommendation

Fit clearance should be controlled to approach 0 um to avoid increased radial runout due to clearance.

High Speed with Long Duty Cycles

To achieve limiting speed with long duty cycles, press fit must not exceed 0.005 mm.

High Speed Application Notes

Interference should be controlled to ≤ 5 um (0.005 mm) to avoid excessive preload increase and frictional heating. Excessive interference fit will cause excessive bearing temperature rise and reduce service life.

Inner Ring Stationary (NGS-SBI Series)

Design shaft diameter according to the tolerance table specifications below.

Full Surface Support Requirement

The bearing inner ring on stationary shaft requires full surface support. The shaft must provide complete support across the entire bearing height range.

Shaft Fit Tolerance Table

The following are recommended shaft fit values for each AXRY-NGS (NGS-SBI) bearing size:

| Model | di [mm] | Tolerance [mm] | J [mm] | H [mm] | T1 [um] | T2 [um] | T3 [um] | Rmax [mm] |

|---|---|---|---|---|---|---|---|---|

| AXRY 120-NGS (-SBI) | 120 | -0.005 / -0.015 | 135 | 40 | 3 | 1.5 | 3 | 0.1 |

| AXRY 180-NGS (-SBI) | 180 | -0.008 / -0.020 | 194 | 43 | 4 | 2 | 4 | 0.1 |

| AXRY 200-NGS (-SBI) | 200 | -0.010 / -0.024 | 215 | 45 | 6 | 2.5 | 5 | 0.1 |

| AXRY 260-NGS (-SBI) | 260 | -0.010 / -0.024 | 280 | 50 | 6 | 3 | 5 | 0.1 |

| AXRY 325-NGS (-SBI) | 325 | -0.012 / -0.028 | 349 | 56 | 7 | 3.5 | 6 | 0.1 |

| AXRY 395-NGS (-SBI) | 395 | -0.012 / -0.028 | 422 | 60 | 8 | 4 | 7 | 0.15 |

| AXRY 460-NGS (-SBI) | 460 | -0.014 / -0.032 | 490 | 65 | 8 | 4 | 7 | 0.15 |

| AXRY 580-NGS (-SBI) | 580 | -0.016 / -0.036 | 615 | 78 | 10 | 5 | 8 | 0.15 |

| AXRY 650-NGS (-SBI) | 650 | -0.018 / -0.040 | 690 | 88 | 10 | 5 | 8 | 0.2 |

Dimension Symbol Legend

- di - Bearing bore diameter

- Tolerance - Shaft diameter tolerance range

- J - Shaft shoulder diameter

- H - Bearing seat height

- T1 - Roundness tolerance

- T2 - Cylindricity tolerance

- T3 - Perpendicularity tolerance

- Rmax - Maximum fillet radius

Related Sections

- Recommended Fits for Housing - Housing fit tolerance selection

- Adjacent Construction Design - Design principles and accuracy requirements

- Bearing Commissioning - Run-in and verification procedures