1.6.1 Accuracy

The accuracy of the SCHNEEBERGER MONORAIL guideway, together with the surrounding structure, determines the motion accuracy of the entire system. Guideway accuracy is crucial for precision positioning and high-quality machining.

The accuracy of linear motion depends on the precision of the machine base on which the guideway is mounted, as well as on the accuracy of the SCHNEEBERGER MONORAIL guideway itself. Accuracy involves dimensional tolerances (height and width deviations) as well as motion accuracy (deviations as the carriage moves along the guideway).

1.6.2 Accuracy Classes of SCHNEEBERGER MONORAIL Guideways

SCHNEEBERGER classifies MONORAIL guideways into different accuracy classes. For this purpose, the height and width dimensional tolerances between the guideway and carriage are controlled.

The tolerances of these dimensions are limited by SCHNEEBERGER in internal production specifications, thus ensuring product consistency and reliability. The accuracy classes define the height and width tolerances of the carriage relative to the guideway; detailed values can be found in the SCHNEEBERGER MONORAIL and AMS product catalogs.

Accuracy Class Description

SCHNEEBERGER offers multiple accuracy classes to meet different application requirements. High accuracy class guideways are suitable for precision machine tools and measuring equipment, while standard accuracy classes are suitable for general industrial applications.

1.6.3 Motion Accuracy

Ideally, the motion of the carriage along the guideway should follow an exact straight-line trajectory. However, due to manufacturing tolerances, the actual motion deviates to some extent. Motion accuracy describes the deviation between the actual motion path of the carriage as it moves along the guideway and the ideal straight-line trajectory.

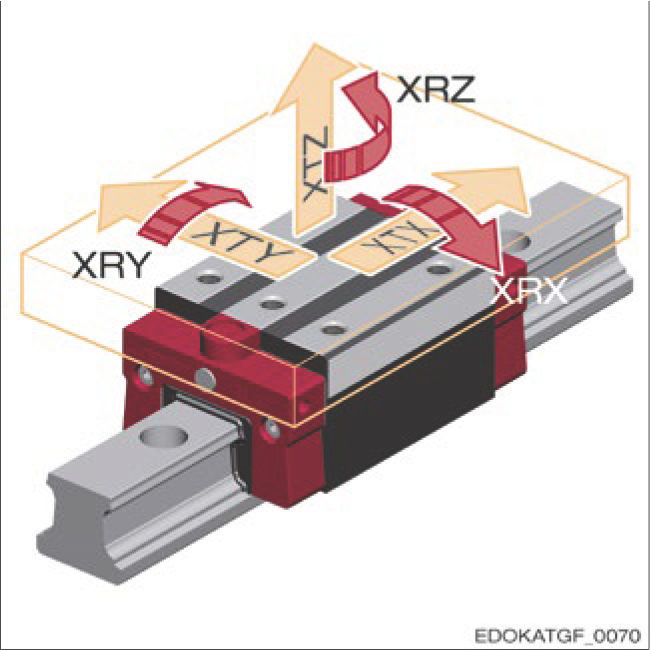

Component Errors of a Single Carriage

A single carriage moving along a guideway produces five component errors. These errors include three rotational motions and two translational motions:

Component errors (five degrees of freedom) of a single carriage.

Component error symbols:

Rotational Deviations (3 types)

- XRX: Rotation about X-axis (direction of motion) - Roll

- XRY: Rotation about Y-axis - Pitch

- XRZ: Rotation about Z-axis - Yaw

Translational Deviations (2 types)

- XTY: Lateral displacement in Y direction

- XTZ: Vertical displacement in Z direction

Abbreviation Definition System

First letter X: Indicates deviation occurring during movement along the X-axis (direction of motion)

Second letter R/T: R = Rotation; T = Translation

Third letter X/Y/Z: Indicates the axis of rotation or direction of displacement

Effects of Component Errors

Taking a machine axis as an example, the geometric behavior is determined by the component errors of individual carriages. When multiple axes are connected together, the component errors interact with each other. Therefore, it is very important to keep the variation of each carriage as small as possible within the system.

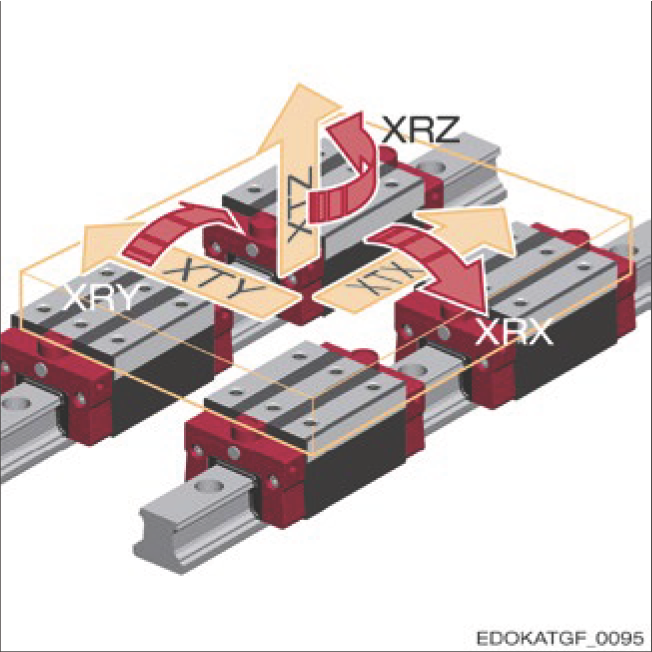

Motion of Multiple Connected Carriages

In practical applications, a configuration with four carriages on two parallel guideways is commonly used. When carriages are connected together via a machine saddle or worktable, the rotational motions of individual carriages are suppressed, and the overall system exhibits only translational motions.

Four connected carriages with rotational movements XRX, XRY and XRZ shown.

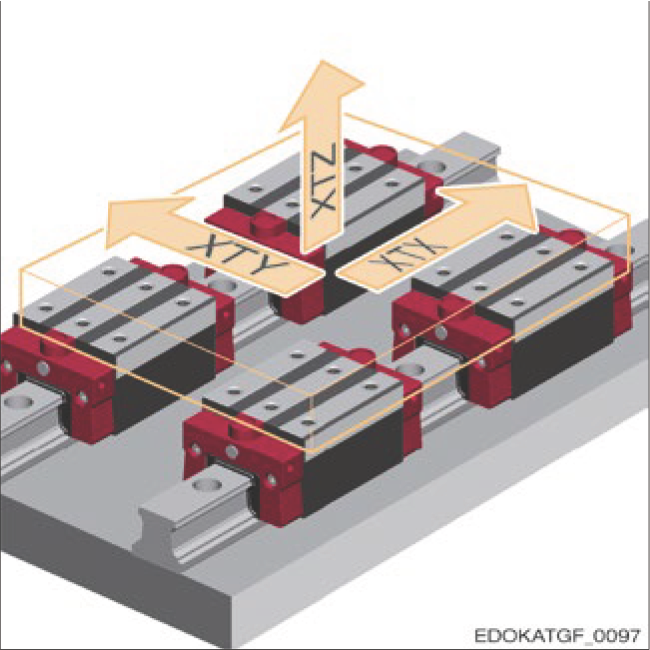

In the overall system, the rotational motions XRX, XRY, and XRZ of individual carriages are no longer visible. The overall motion is the combined result of individual component motions. The system of connected carriages retains only translational degrees of freedom:

Four connected carriages with only translational movements XTX, XTY and XTZ.

Motion Characteristics of Connected Carriages

When multiple carriages are rigidly connected, the rotational degrees of freedom of individual carriages are constrained, and the system as a whole exhibits only three translational directions of motion (XTX, XTY, XTZ). This is why precision machine tools typically employ a four-carriage, dual-guideway configuration.

1.6.4 Factors Affecting Motion Accuracy

The motion accuracy of SCHNEEBERGER MONORAIL guideways is affected not only by the manufacturing precision of the rolling elements, but also by the following factors. These factors can be classified into three categories based on their range of influence:

Long-range Variations

Factors affecting the entire stroke length

- Geometric errors of guideway tracks (straightness, parallelism)

- Geometric errors of machine base positioning surfaces

- Rigidity and accuracy of surrounding structures

Medium-range Variations

Periodic variations with period equal to screw pitch

- Local deformation of guideway due to screw forces

- Position tolerances of guideway holes

- Inconsistency of screw tightening torques

Short-range Variations

High-frequency periodic variations

- Travel pulsation of carriage (periodic contact of rolling elements)

- Transition points of multi-segment guideways

- Minor differences in rolling element diameters

Geometric Errors of Connecting Structures

To obtain high-precision guidance, the positioning surfaces of the connecting structures must also have high precision. Additional geometric errors come from the accuracy and rigidity of the machine, as well as the influence of the overall surrounding structure. The motion accuracy of the guideway ultimately depends on the combined result of the guideway's own accuracy and the accuracy of the support surfaces.

Effects of Screw Forces

The screw forces during guideway installation cause local compression and deformation. The following factors affect this deformation:

- Magnitude of screw tightening torque

- Lubrication condition of screw head (affects head friction)

- Flatness of support surfaces

- Contact condition between guideway and support surface

1.6.5 Travel Pulsation

Travel pulsation refers to the small periodic motions in the XTY (lateral) and XTZ (vertical) directions that occur as the carriage moves along the guideway. This is caused by the periodic contact as rolling elements enter and leave the load zone.

Causes of Travel Pulsation

Travel pulsation is mainly caused by the following factors:

- Impact when rolling elements enter the load zone

- Release when rolling elements leave the load zone

- Minor differences in rolling element diameters

- Elastic deformation at rolling element and track contact points

Factors Affecting Travel Pulsation

The amplitude of travel pulsation can be controlled by the following parameters:

Carriage Length L

Longer carriages have more rolling elements loaded simultaneously, which can average out the influence of individual rolling elements, thereby reducing travel pulsation.

Preload Class V

Lower preload can reduce the impact force when rolling elements enter the load zone, thereby reducing the amplitude of travel pulsation.

Design Recommendations

Longer carriages and lower preload V can reduce travel pulsation.

Note: Lower preload reduces system rigidity; a balance between accuracy and rigidity must be achieved.

SCHNEEBERGER pays special attention to the design of the rolling element recirculation unit and entry zones. By optimizing the geometry of these areas, rolling elements can smoothly enter and leave the load zone, thereby minimizing travel pulsation.

1.6.6 Measures to Improve Accuracy

The following list provides an overview of measures that can be used to improve motion accuracy. These measures cover machine design, guideway selection, and installation methods:

Machine Design

- Use the most rigid machine structure possible

- Precision-machine guideway support surfaces

- Use larger guideway spacing (gauge) and carriage spacing

Guideway Selection

- Select high accuracy class guideways

- Select guideway pairs with similar motion behavior (pairing system, see Section 4.6)

- Use longer carriages to reduce travel pulsation

Installation Configuration

- Install guideways with single-side lateral datum

- Select smaller guideway hole spacing

- Use dual-guideway configuration with at least two carriages per guideway

Screw Installation

- Reduce screw tightening torque (while ensuring sufficient load capacity)

- Maintain consistent screw tightening torques

- Properly lubricate screw heads to reduce friction

Pairing System Description

SCHNEEBERGER offers a pairing system that allows selection of guideway and carriage combinations with similar motion behavior characteristics. Paired guideways used in the same system can further reduce motion errors. For detailed information, please refer to Section 4.6 - Accuracy.