General Notes

Fit accuracy and geometrically correct design of all connecting components have a direct influence on the precision requirements and dynamic characteristics of the bearing.

Please refer to the structural design notes in the general catalog section.

Surface Roughness Requirements

Ra 0.8 μm - Recommended surface roughness for shaft fit surfaces

Rotating Inner Ring - AXCR-U Series

AXCR-U series has standard bore tolerance (0/negative).

Fit Design Principles

On the rotating shaft, the bearing inner ring should be supported over the entire surface. The shaft should be designed according to h5 fit. This way, the bearing bore tolerance produces a transition fit with a slight tendency towards clearance fit.

Maximum Accuracy Requirements

For the highest accuracy requirements of rotating inner rings, a 0 μm clearance fit must be targeted; existing clearance fits may increase radial runout.

High Dynamic Requirements

At high speeds (ndm > 35,000 mm/min) and longer operating times (>10%), interference fit must not exceed 5 μm.

Stationary Inner Ring - AXCR-U Series

Stationary, bolt-connected inner rings do not require special fits and can also be installed with clearance to the shaft. If the inner ring requires centering, it is designed as:

- For AXCR-U inner rings with standard bore tolerance (0/negative), use g6 or similar tolerance

Interference fits should be avoided to prevent the risk of increased bearing preload.

AXCR-U Series Shaft Fit Tolerance Table

| Model | Shaft Ø di [mm] | Bearing Bore Tolerance Range [mm] | Inner Ring Stationary | Inner Ring Rotating | Rmax [mm] | ||||

|---|---|---|---|---|---|---|---|---|---|

| Shaft Tolerance g6 [mm] | T1, T2, T3 [μm] | Shaft Tolerance h5 [mm] | T1 Roundness [μm] | T2 Parallelism [μm] | T3 Perpendicularity [μm] | ||||

| AXCR 80-U | 80 | 0 / -0.009 | -0.010 / -0.029 | 5 | 0 / -0.013 | 3 | 1.5 | 3 | 0.1 |

| AXCR 90-U | 90 | 0 / -0.010 | -0.012 / -0.034 | 6 | 0 / -0.015 | 4 | 2 | 4 | 0.1 |

| AXCR 115-U | 115 | 0 / -0.010 | -0.012 / -0.034 | 6 | 0 / -0.015 | 4 | 2 | 4 | 0.1 |

| AXCR 160-U | 160 | 0 / -0.013 | -0.014 / -0.039 | 8 | 0 / -0.018 | 5 | 2.5 | 5 | 0.1 |

| AXCR 210-U | 210 | 0 / -0.015 | -0.015 / -0.044 | 10 | 0 / -0.020 | 7 | 3.5 | 7 | 0.3 |

| AXCR 270-U | 270 | 0 / -0.018 | -0.017 / -0.049 | 12 | 0 / -0.023 | 8 | 4 | 8 | 0.3 |

| AXCR 350-U | 350 | 0 / -0.023 | -0.018 / -0.054 | 13 | 0 / -0.025 | 9 | 4.5 | 9 | 0.3 |

| AXCR 360-U | 360 | 0 / -0.023 | -0.018 / -0.054 | 13 | 0 / -0.025 | 9 | 4.5 | 9 | 0.3 |

| AXCR 540-U | 540 | 0 / -0.030 | -0.022 / -0.066 | 16 | 0 / -0.032 | 11 | 5.5 | 11 | 0.3 |

Rotating Inner Ring - AXCR-S Series

AXCR-S series has bore tolerance (0/positive).

Fit Design Principles

On the rotating shaft, the bearing inner ring should be supported over the entire surface. The shaft should be designed according to k5 fit. This way, the bearing bore tolerance produces a transition fit with a slight tendency towards clearance fit.

For clearance fit design, please refer to the guidelines in the adjacent construction design section.

Maximum Accuracy Requirements

For the highest accuracy requirements of rotating inner rings, a 0 μm clearance fit must be targeted; existing clearance fits may increase radial runout.

High Dynamic Requirements

At high speeds (ndm > 35,000 mm/min) and longer operating times, interference fit must not exceed 5 μm.

Stationary Inner Ring - AXCR-S Series

Stationary, bolt-connected inner rings do not require special fits and can also be installed with clearance to the shaft. If the inner ring requires centering, it is designed as:

- For AXCR-S inner rings with bore tolerance (0/positive), use j6 or similar tolerance

Interference fits should be avoided to prevent the risk of increased bearing preload.

AXCR-S Series Shaft Fit Tolerance Table

| Model | Shaft Ø di [mm] | Bearing Bore Tolerance Range [mm] | Inner Ring Stationary | Inner Ring Rotating | Rmax [mm] | ||||

|---|---|---|---|---|---|---|---|---|---|

| Shaft Tolerance j6 [mm] | T1, T2, T3 [μm] | Shaft Tolerance k5 [mm] | T1 Roundness [μm] | T2 Parallelism [μm] | T3 Perpendicularity [μm] | ||||

| AXCR 130-S | 130 | 0 / +0.025 | +0.014 / -0.011 | 8 | +0.021 / +0.003 | 5 | 2.5 | 5 | 0.1 |

| AXCR 150-S | 150 | 0 / +0.025 | +0.014 / -0.011 | 8 | +0.021 / +0.003 | 5 | 2.5 | 5 | 0.1 |

| AXCR 180-S | 180 | 0 / +0.025 | +0.014 / -0.011 | 8 | +0.021 / +0.003 | 5 | 2.5 | 5 | 0.1 |

| AXCR 220-S | 220 | 0 / +0.029 | +0.016 / -0.013 | 10 | +0.024 / +0.004 | 7 | 3.5 | 7 | 0.3 |

| AXCR 280-S | 280 | 0 / +0.032 | +0.016 / -0.016 | 12 | +0.027 / +0.004 | 8 | 4 | 8 | 0.3 |

| AXCR 360-S | 360 | 0 / +0.036 | +0.018 / -0.018 | 13 | +0.029 / +0.004 | 9 | 4.5 | 9 | 0.3 |

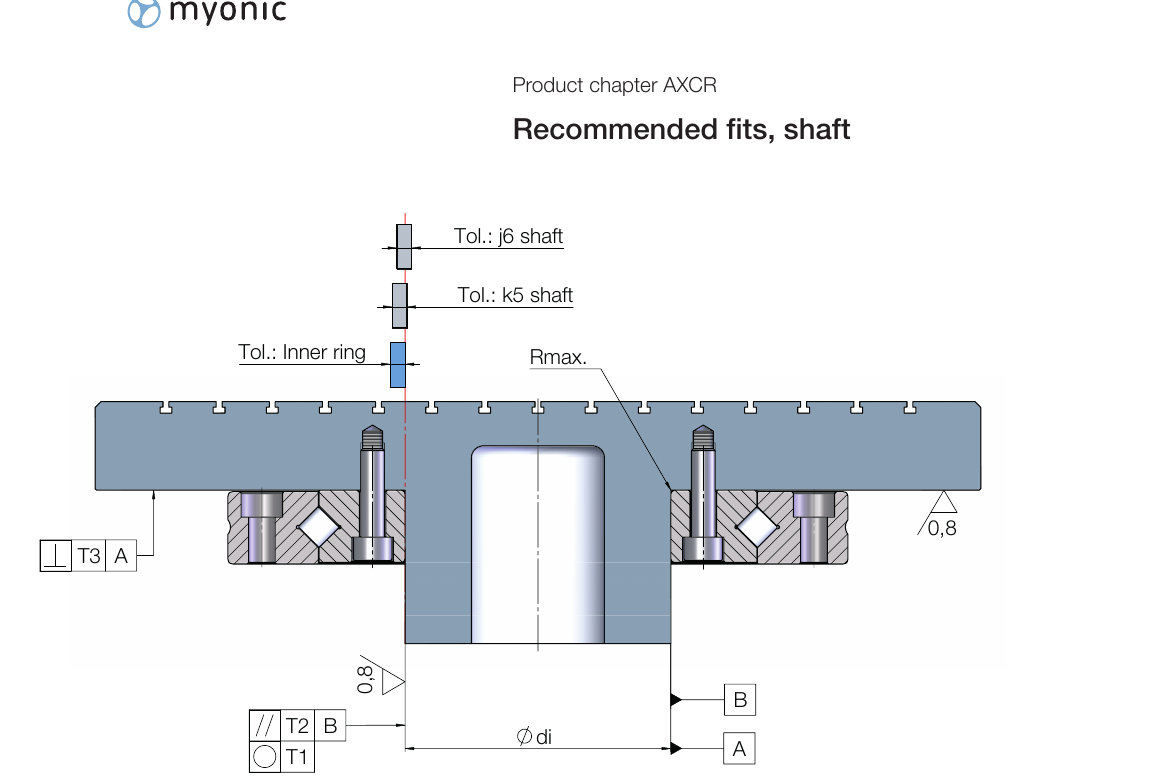

Shaft Fit Dimension Diagram

Dimension Symbol Legend

- di - Bearing bore / shaft diameter

- T1 - Roundness tolerance

- T2 - Parallelism tolerance

- T3 - Perpendicularity tolerance

- Rmax - Maximum fillet radius

- g6, h5 - AXCR-U shaft tolerance ranges

- j6, k5 - AXCR-S shaft tolerance ranges

Notes

Important: Shaft Surface Quality

- Surface roughness: Ra ≤ 0.8 μm

- Roundness: According to model requirements (see table above)

- Parallelism: Should be within tolerance range

- Perpendicularity: Perpendicularity of shaft shoulder to shaft journal is important

- The above data are recommended values; adjustments may be required based on specific application conditions

- High precision applications may require tighter tolerances

- All mating surfaces should be cleaned and inspected before installation

- For clearance fit design, please refer to the guidelines in the adjacent construction design section