7.1 Product Characteristics

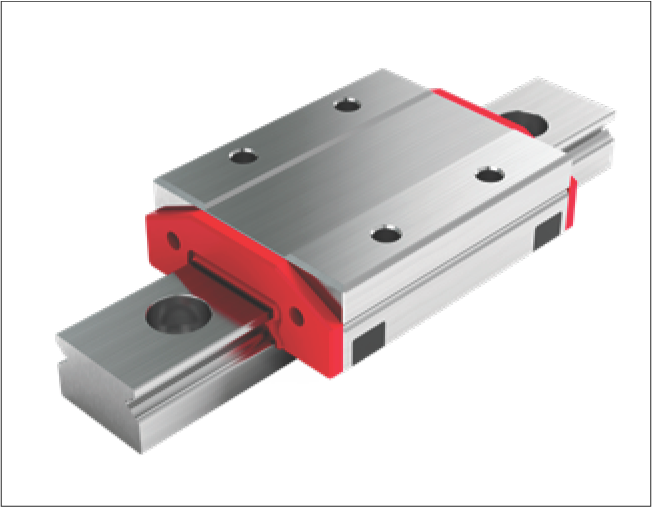

7.1.1 Carriage Interchangeability

Due to the precisely consistent manufacturing dimensions of the carriages, they can be freely interchanged with other carriages (carriage uniformity system). This greatly simplifies inventory and maintenance work.

Note:

MINISCALE PLUS carriages and guide rails are always matched to each other and therefore delivered as a set (carriage mounted on guide rail) - (see Chapter 18.1).

Carriage Uniformity System

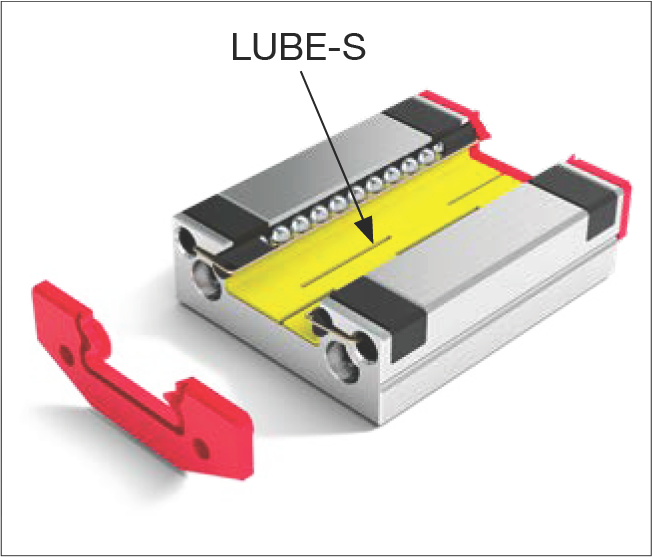

7.1.2 LUBE-S Long-Term Lubrication from SCHNEEBERGER

SCHNEEBERGER's long-term lubrication solution LUBE-S is described in detail in Chapter 8.1. LUBE-S enables maintenance-free operation for up to 20,000 km, requires no additional space, and is beneficial for both environmental and short-stroke applications.

Note:

Warranty is only provided when using lubricants tested and approved by SCHNEEBERGER.

LUBE-S Long-Term Lubrication

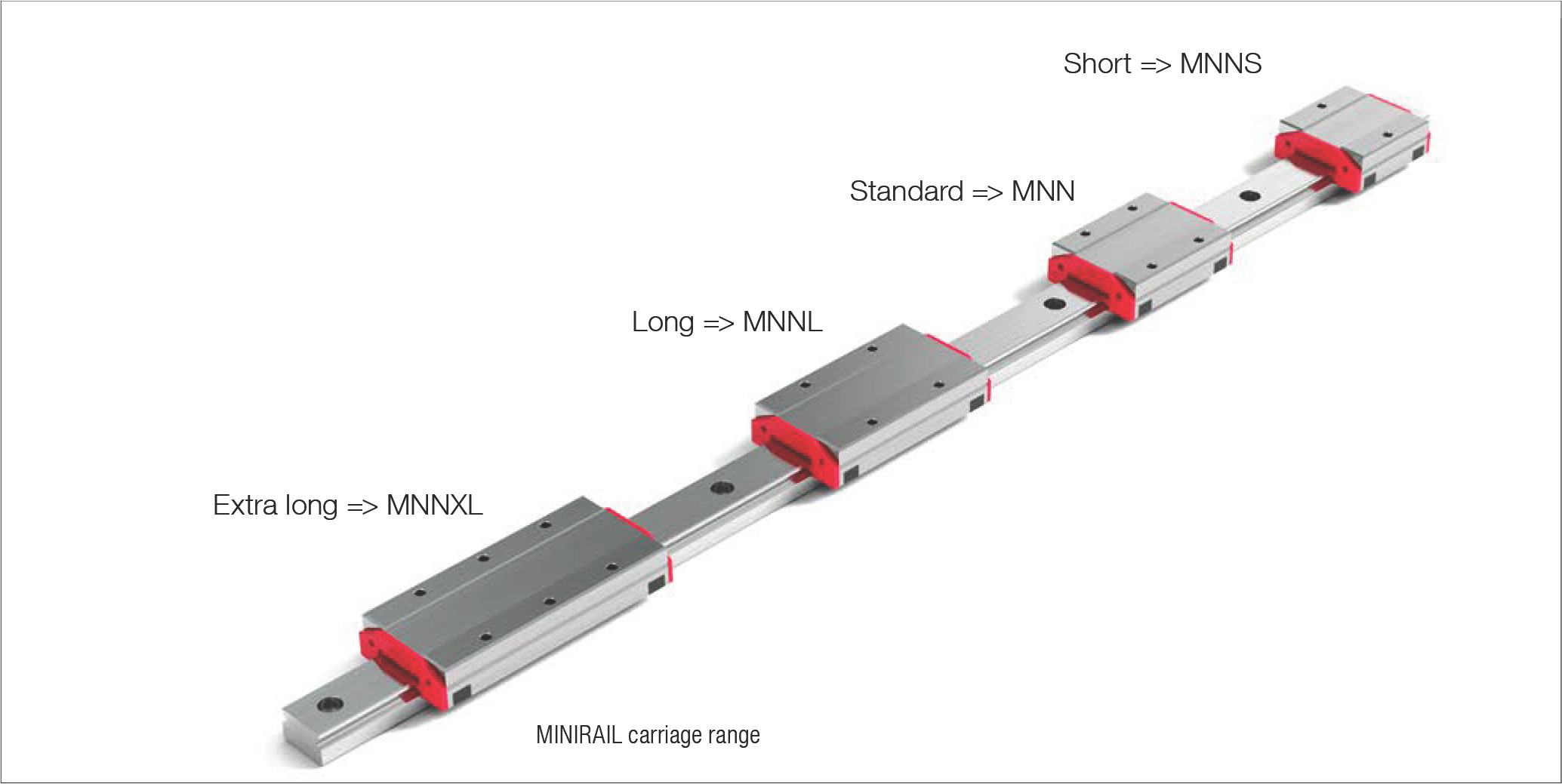

7.1.3 Carriage Range

Various carriage lengths from short to extra-long, with corresponding load capacities, provide greater flexibility when designing motion axes.

Standard => MNN Short => MNNS Extra Long => MNNXL Long => MNNL MINIRAIL Carriage Range

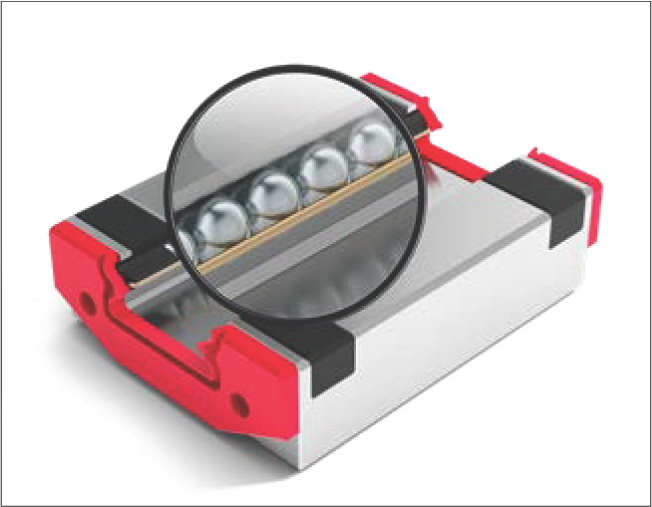

7.1.4 Speeds and Accelerations

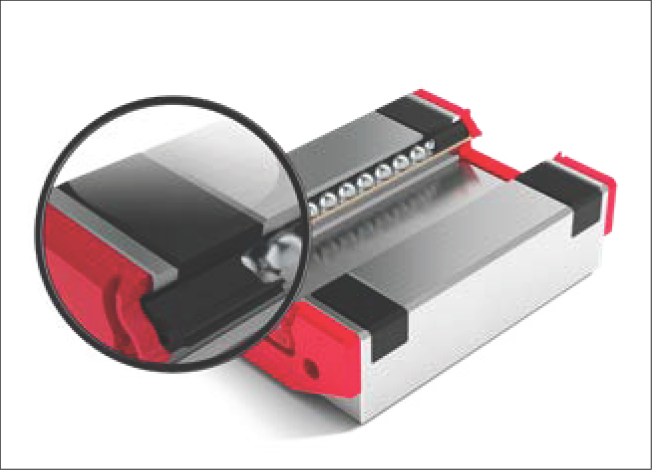

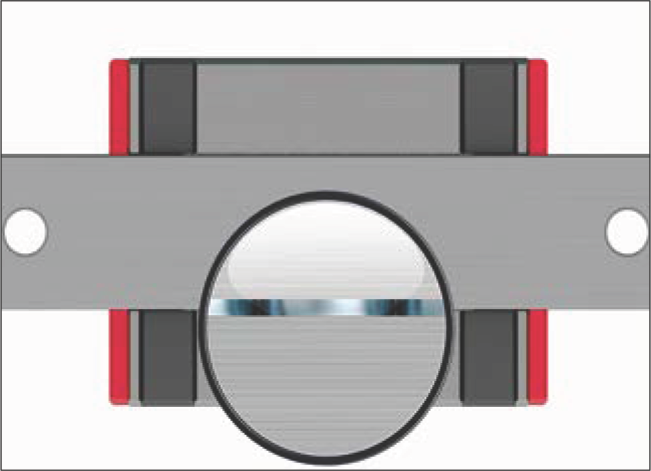

The innovative embedded ball circulation design in the carriage allows speeds up to 5 m/s and accelerations up to 300 m/s².

Enlarged View of Ball Recirculation in Carriage

7.1.5 High Load Capacity

The Gothic arch profile of the guide rail track allows high load capacity.

Gothic Arch Profile of Guide Rail Track

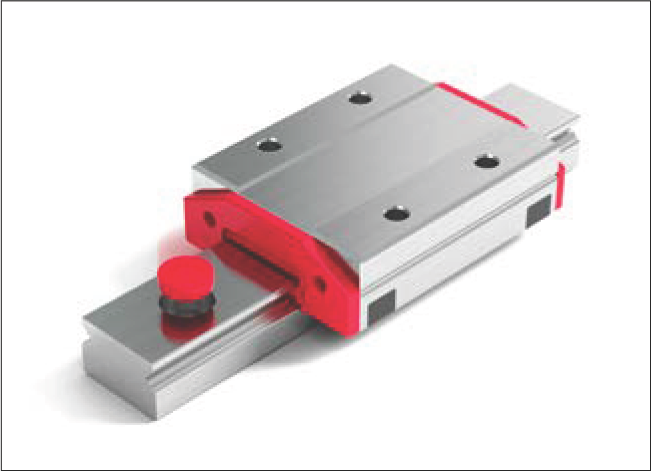

7.1.6 Simple Installation and Maintenance

Whether the carriage is moving along the guide rail or being prepared for installation, the ball bearings are always held in place by a retaining wire. This makes handling easier and is a prerequisite for simple installation and replacement of carriages.

Retaining Wire Holding Balls in Position

7.1.7 Outstanding Robustness

The carriages and guide rails are made of through-hardened stainless steel. Therefore, they are very suitable for use in the most demanding applications.

Made of Corrosion-Resistant, Through-Hardened Steel

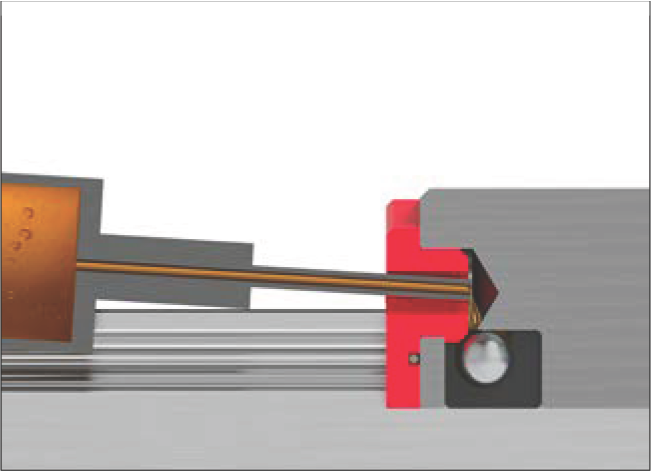

7.1.8 Precision Lubrication Concept

MINIRAIL is delivered unlubricated as standard, allowing you to determine the optimal lubrication method according to the respective application (see Chapter 7.2.12 "Lubricating MINIRAIL").

MINIRAIL Oil Lubrication

Each wiper on the carriage has two lubrication holes so that the left and right ball circulation paths can be separately oil lubricated. This ensures that the carriage tracks can be supplied with lubricant regardless of the installation direction.

Also consider the long-term lubrication option LUBE-S in Chapter 8.1.

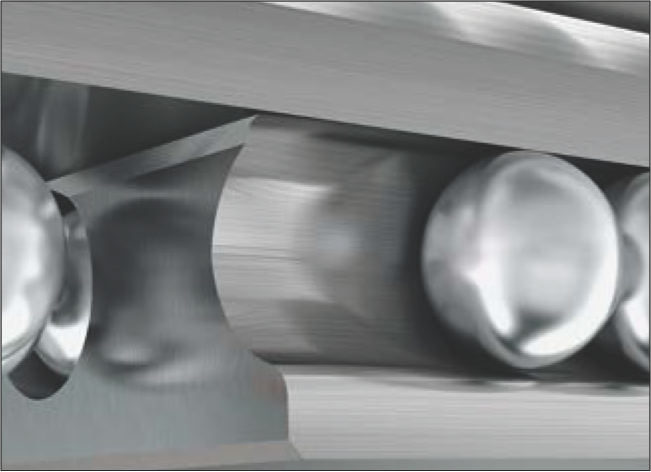

7.1.9 Excellent Running Characteristics

The ball circulation, transitions, and run-in areas on the carriage are designed for consistent redirection of ball bearings. They ensure optimal control of the significant centrifugal forces involved with minimal friction.

Polished Run-In Areas

7.1.10 Maximum Contamination Protection

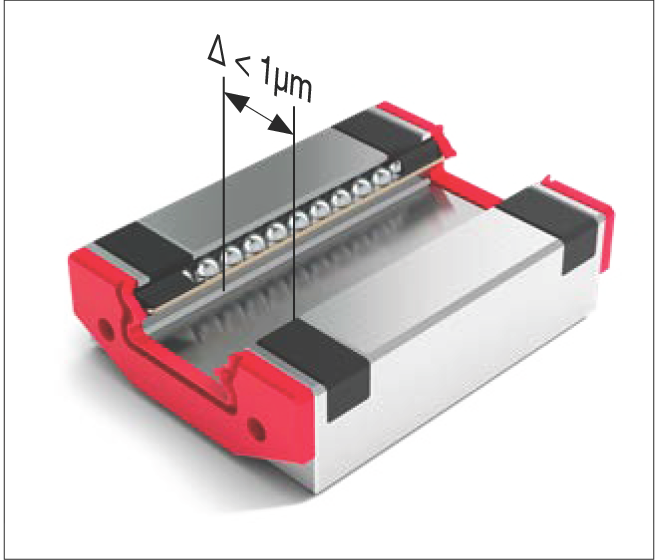

The ultra-precision manufacturing of the carriage and guide rail ensures minimal clearance between them. This prevents dirt particles from entering the carriage.

Minimal Clearance Between Carriage and Guide Rail

Carriages are equipped with profile wipers as standard. They snap into place and can therefore be easily replaced. Alternative variants (e.g., low-friction or gap wipers) are described in Chapter 9.2.

Detachable Wipers

To prevent dirt accumulation, mounting holes in the guide rail can be sealed with plastic plugs (see Chapter 9.1).

Plastic Plugs for Sealing