Life Rating L

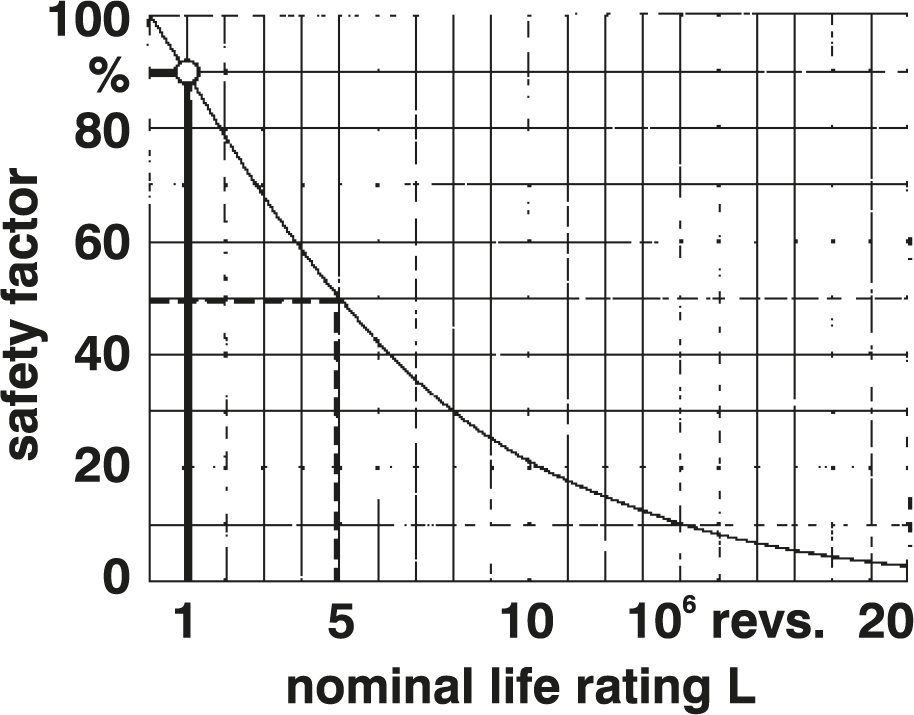

The life rating is a calculated rated operating period for a given load and speed, at the end of which 90% of identical ball screws are expected to show no signs of fatigue (pitting).

Example: If a safety factor of 50% (instead of 90%) is used, the calculation will yield five times the life rating value.

Influencing Factors

The actual service life is significantly influenced by the design, material, and production quality of the ball screw. This is also the reason for our long-term success.

The machine manufacturer or user must be responsible for protecting the ball screw from contaminants that may cause wear and preload loss.

Dynamic Load Rating Cam

Dynamic Load Rating

Standard AM Design

- See values in data sheets

- Calculated according to German standard DIN 69051 Part 4

Mean Load Fm, nm, (Fw)

The Mean Load

According to DIN 69051 Part 4, it is necessary to determine the axial forces Fai for different operating intervals (roughing, finishing, rapid movement, stop), considering the corresponding speeds ni and time percentages qi, and convert them to representative mean values through formulas: Fm, nm.

The mean load calculated from the load spectrum is the effective mean load Fmw.

Preload Consideration

Preload Consideration

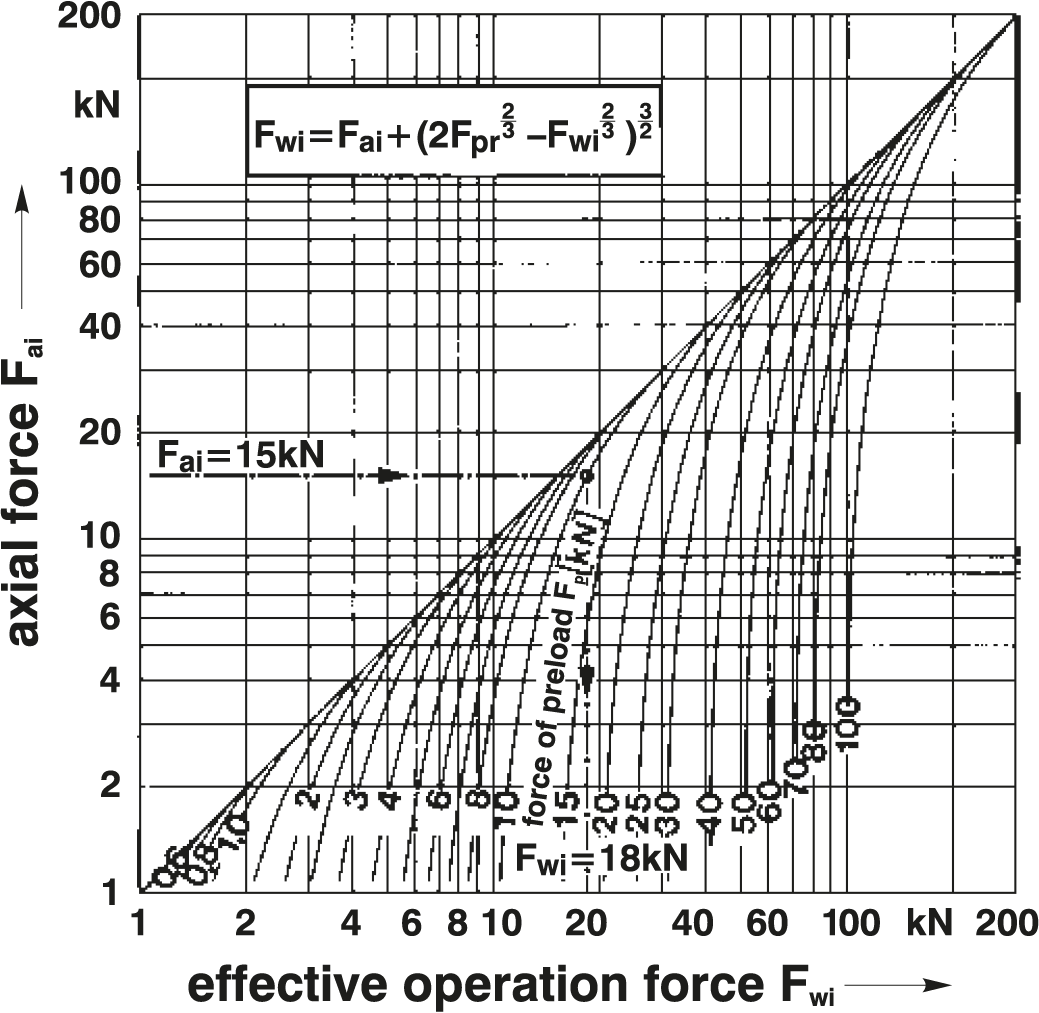

Ball screws for high dynamic applications (high speed) require high nut preload Fpr, which must be considered when calculating life rating Lh. When considering Fpr, use the effective force Fwi of the operating interval axial force Fai (see pages 9+12).

Effective Force Calculation

The relevant operating force Fai gains additional force due to preload Fpr.

The resulting effective operating force can be obtained from the diagram below.

Important: Use Fwi (not Fai) for load spectrum calculation in life rating.

Relationship between effective operating force Fwi, axial force Fai, and preload Fpr

Calculation of the Nominal Life Rating (Fatigue)

Calculation of the Nominal Life Rating (Fatigue)

Step 1: Fatigue Starting Point

Fatigue L106 statistically begins after multiples of 106 load revolutions.

Step 2: Screw Operating Time

The speed nm determines the fatigue duration = screw operating time Lh1 (hours).

Step 3: Machine Operating Time

The machine operating time Lhm (hours) is determined by the shaft duty factor ED.

Load Direction Factor λ

- λ = 1: Unidirectional load

- λ = 2: Bidirectional equally distributed load

(Unequally distributed load directions require separate calculation for each nut part)